28.318

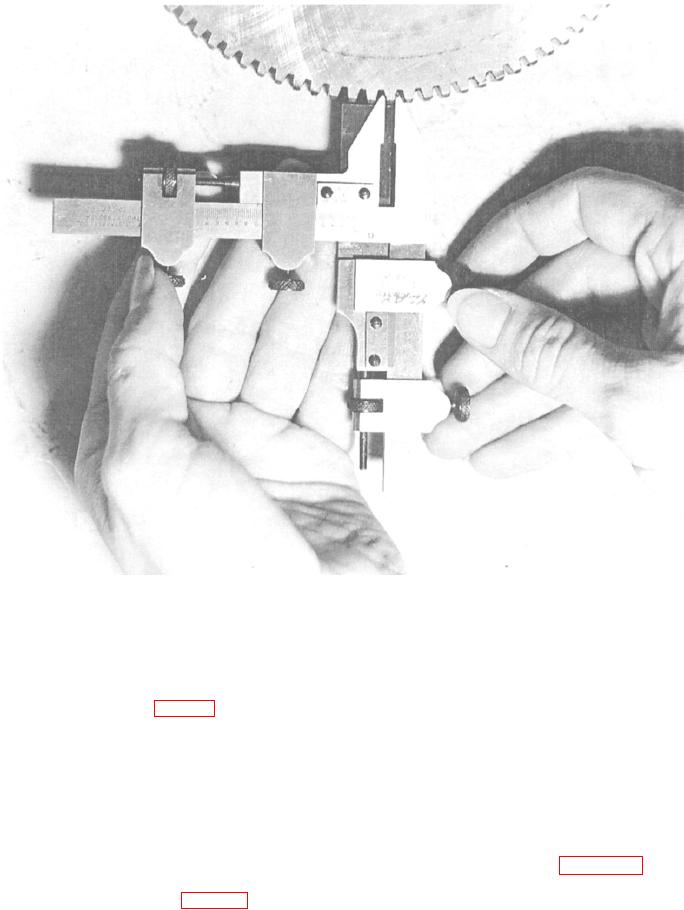

Figure 1-14.--Gear tooth vernier.

Rotate the cutter sufficiently to bring the tooth face

Gear Tooth Vernier

into contact with the gauge blade. If the angle of

clearance on the tooth is correct, it will correspond

Use a gear tooth vernier (fig. 1-14) to measure the

with the angle of the gauge blade. Cutter clearance

thickness of a gear tooth on the pitch circle and the

gauges that have an adjustable gauge blade to check

distance from the top of the tooth to the pitch chord, at

clearance angles of 0 to 30 are also available.

the same time. Read the vernier scale on this tool in

the same way as other verniers, but note that

graduations on the main scale are 0.020 inch apart

Adjustable Parallel

instead of 0.025 inch.

Cutter Clearance Gauge

The adjustable parallel in figure 1-16 consists of

two wedges connected on their inclined surfaces by a

sliding dovetail. An adjustable parallel can be locked

The cutter clearance gauge (fig. 1-15) is one of

the simplest to use. You can gauge clearance on all

at any height between its maximum and minimum

styles of plain milling cutters that have more than 8

limits. This instrument, constructed to about the same

teeth and a diameter range from 1/2 inch to 8 inches.

accuracy of dimensions as parallel blocks, is very useful

To gauge a tooth with this instrument, bring the

to level and position setups in a milling machine or in a

surfaces of the "V" into contact with the cutter and

shaper vise. You should normally use an outside

lower the gauge blade to the tooth to be gauged.

micrometer to set the adjustable parallel for height.

1-14