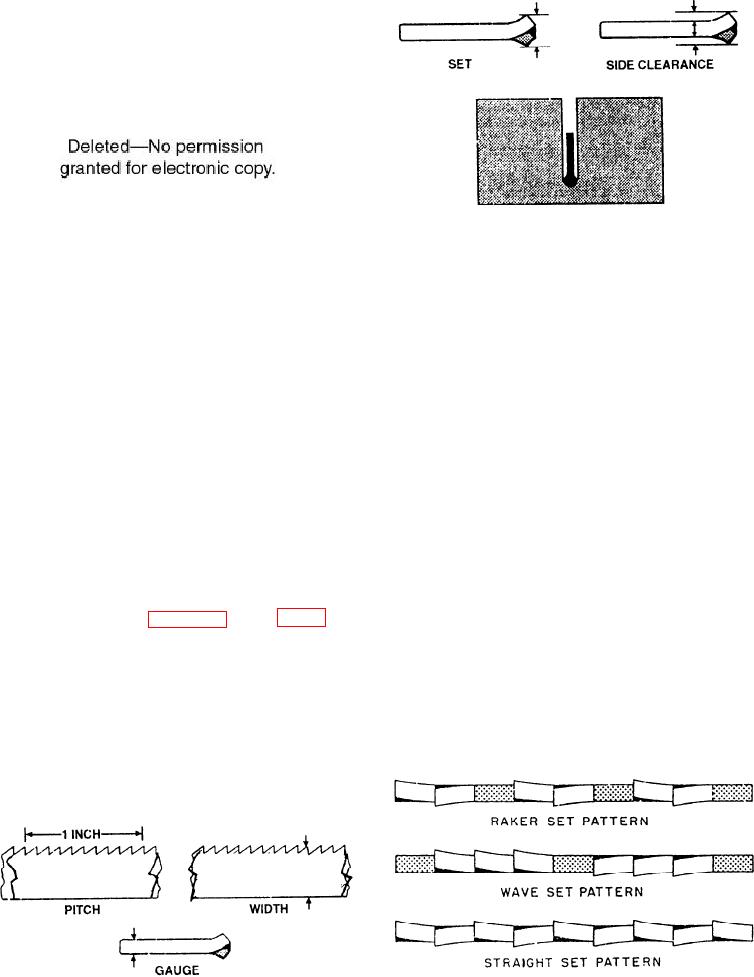

Figure 4-7.--Set and side clearance.

SET: The bend or spread given to the teeth to

provide clearance for the body or band back when you

make a cut.

SIDE CLEARANCE: The difference between

the dimension of the band back (gauge) and the set of

the teeth. Side clearance provides running room for

the band back in the kerf or cut. Without side

Figure 4-5.--Tiltable (contour) metal-cutting bandsaw.

clearance, a band will bind in the kerf.

SET PATTERN: One of three distinct patterns

help you understand band tool terminology for saws,

(raker, wave, and straight) in which teeth are set.

files, and polishing bands.

Raker set bands are generally used for solid cross

section work. Wave set bands are used to cut hollow

Saw Bands

materials, such as pipe and tubing, and for other work

where there is a great deal of variation in thickness.

A saw band has the following characteristics

Straight set bands are not used to any great extent to

cut metal.

PITCH: The number of teeth per linear inch.

TEMPER: The degree of hardness of the teeth,

WIDTH: The distance across the flat face of the

indicated by the letters A and B, temper A being the

band. The width measurement is always expressed in

harder. Temper A bands are used for practically all

inches, or fractions of an inch.

bandsaw metal cutting work.

GAUGE: The thickness of the band back. This

measurement is expressed in thousandths of an inch.

Figure 4-8.--Set pattern.

Figure 4-6.--Pitch, width, and gauge.

4-5