velocity increases. We cannot cover the details of

adjustment because different machines use different

methods. Consult the manufacturer's technical

manual for your particular machine and learn how to

set up the various speeds available.

FEEDS. --Though manual feeding of the work

to the saw is satisfactory to cut metals up to 1 inch

thick, power feeding generally provides better

results and will be much safer for the operator.

Regardless of whether you use power or manual

feed, it is important not to crowd the saw because

the band will tend to bend and twist. However, feed

pressure must not be so light that the teeth slip

across the material instead of cutting through

because this rapidly dulls the teeth. The job

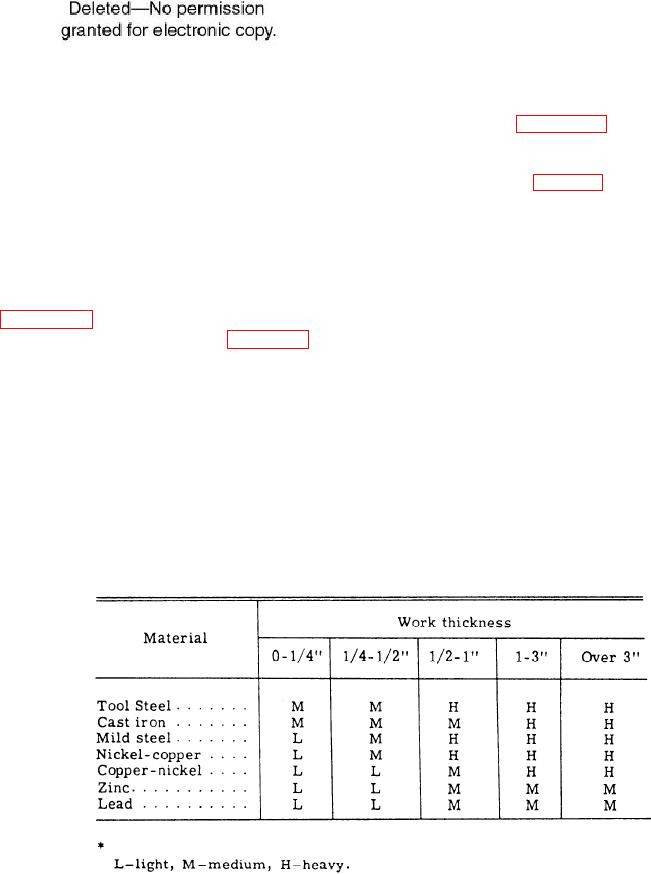

feed pressures to cut any of the materials listed on

the outer ring of the dial. In the absence of a job

selector, you can use table 4-1 as a guide to select

feed pressures for hard, medium hard, and soft

metals.

The power feed controls vary with different

Figure 4-15.--Saw band width selection guides.

makes of bandsaws and even with different models of

the same make; therefore, we will not describe them

here. Consult the manufacturer's technical manual

and study the particular machine to learn its power

feed arrangement and control.

Sizing, Splicing, And Installing Bands

BAND SPEEDS.--The rate at which the saw

band travels in feet per minute from wheel to wheel is

the saw band velocity. Saw band velocity has con-

Most contour cutting type bandsaws are provided

siderable effect upon both the smoothness of the cut

with a buttwelder-grinder combination, you should

surfaces and the life of the band. The higher the band

use it to join saw bands that come in bulk stock coil

velocity, the smoother the cut; however, heat

form, and to join broken band loops. The butt welder

generated at the cutting point increases as band

is usually attached to the saw machine, as shown in

Table 4-1.--Feed Pressures for Hard, Medium Hard, and Soft Metal

4-9