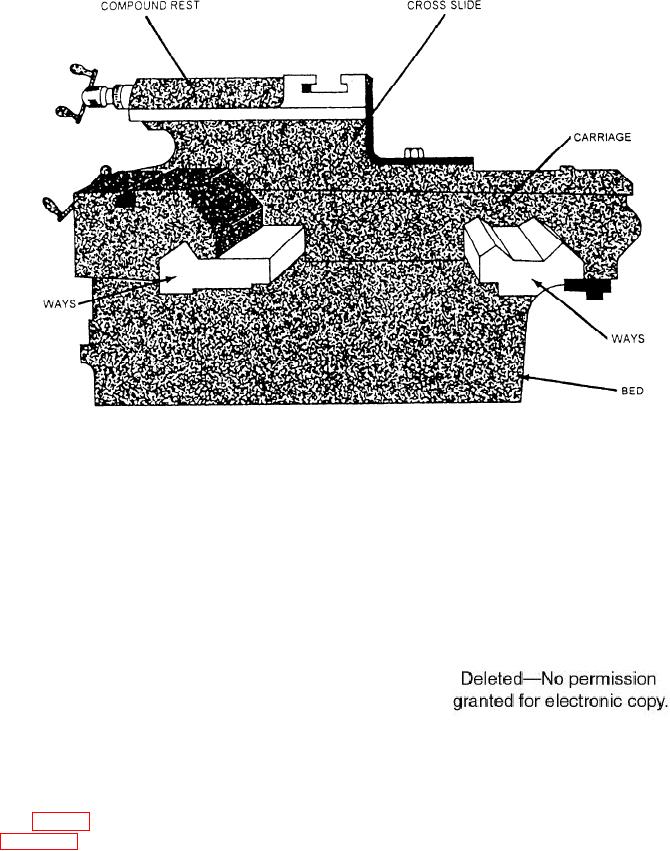

Figure 6-7.--Side view of a carriage mounted on the bed.

Before you insert a center or tooling into the

spindle, carefully clean the tapered shank and wipe

out the tapered hole of the spindle. After you put a

drill or a reamer into the tapered hole of the spindle,

be sure to tighten it in the spindle so that the tool will

not revolve. If the drill or reamer is allowed to

revolve, it will score the tapered hole and destroy its

accuracy. The spindle of the tailstock is engraved

with graduations that help in determining the depth of

a cut when you drill or ream.

CARRIAGE

The carriage carries the cross-feed slide and the

compound rest that, in turn, carries the cutting tool in

the toolpost. The carriage slides on the ways along

the bed (fig. 6-7).

Figure 6-8 shows a top view of the carriage. The

wings of the H-shaped saddle contain the bearing

surfaces, which are fitted to the V-ways of the bed.

The crosspiece is machined to form a dovetail for the

cross-feed slide. The cross-feed slide is closely fitted

to the dovetail and has a tapered gib that fits between

the carriage dovetail and the matching dovetail of the

Figure 6-8.--Carriage (top view).

cross-feed slide. The gib permits small adjustments

to remove any looseness between the two parts. The

6-6