3. Drill and bore to the required size (within

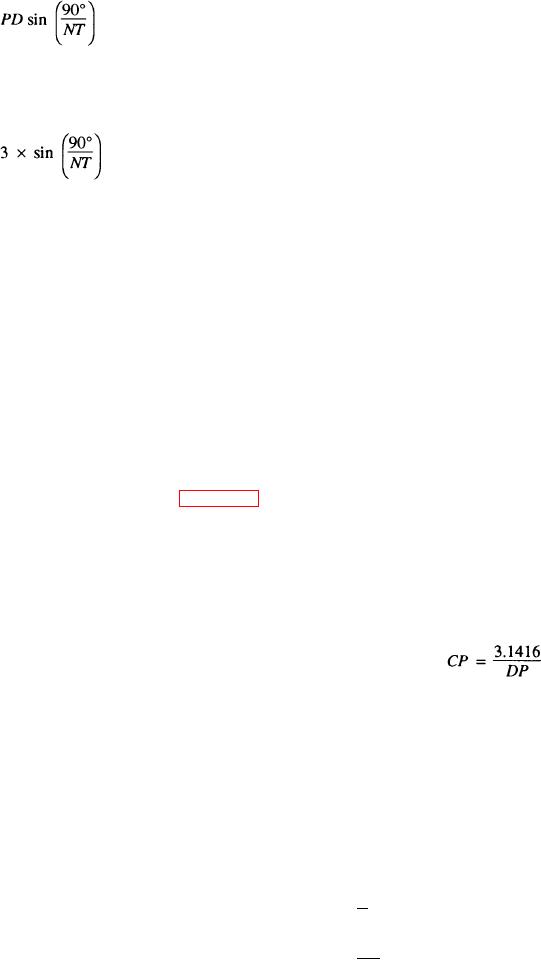

The formula to find the chordal tooth thickness is

tolerance).

tc =

4. Remove the blank from the lathe and press it

on a mandrel.

5. Set up the mandrel on the milling machine

For example,

between the centers of the index head and the

footstock. Dial in within tolerance.

7. Select a No. 5 involute gear cutter (8 pitch) and

tc =

mount and center it.

8. Set the index head to index 24 divisions.

= 3 sin 345″

9. Start the milling machine spindle and move the

table up until the cutter just touches the gear

= 3 0.0654

feed handwheel to zero, then hand feed the

table up toward the cutter slightly less than the

whole depth of the tooth.

= 3 0.1962 inch

10. Cut one tooth groove. Then index the work-

piece for one division and take another cut.

Check the tooth dimensions with a vernier gear

(NOTE: Mathematics, Volume II-A, NAVEDTRA

tooth caliper as described previously. Make the

10062, and various machinist's handbooks contain

required adjustments to provide an accurately

information on trigonometric functions.)

"sized" tooth.

Now set the vertical scale of the gear tooth vernier

11. Continue indexing and cutting until the teeth

caliper to 0.128 inch. Adjust the caliper so the jaws

are cut around the circumference of the

workpiece.

the reading on the horizontal scale is 0.1962 inch, the

When you machine a rack, space the teeth by

tooth has correct dimensions; if the dimension is

moving the work table an amount equal to the circular

greater, the whole depth (WD) is too shallow; if the

pitch of the gear for each tooth cut. Calculate the circular

reading is less, the whole depth (WD) is too deep.

pitch by dividing 3.1416 by the diametral pitch:

Sometimes you cannot determine the outside

diameter of a gear or the number of teeth from available

information. However, if you can find a gear dimension

and a tooth dimension, you can put these dimensions

into one or more of the formulas in Appendix II and

calculate the required dimensions.

You do not need to make calculations for corrected

addendum and chordal pitch to check rack teeth

dimensions. On racks the addendum is a straight line

MACHINING THE GEAR

dimension and the tooth thickness is one-half the linear

pitch.

Use the following procedures to make a gear with

the dimensions given in the preceding example:

1. Select and cut a piece of stock to make the

blank. Allow at least 1/8 inch excess material

on the diameter and thickness of the blank for

A helix is a line that spirals around a cylindrical

cleanup cuts.

object, like a stripe that spirals around a barber pole.

2. Mount the stock in a chuck on a lathe. At the

A helical gear is a gear whose teeth spiral around

center of the blank, face an area slightly larger

the gear body. Helical gears transmit motion from one

than the diameter of the required bore.

shaft to another. The shafts can be either parallel or set

14-5