Chapter 3—ENGINE MAINTENANCE

danger that the piston will strike valves that may

be open and extending into the cylinder. Make

certain that any gears removed are replaced in the

original position. Special punch marks, or

numbers (figure 3-24), are usually found on gear

teeth that should mate. If they are not present,

make identifying marks to facilitate the correct

mating of the gears later.

Bearing, bushing, and gear clearances must be

properly maintained. If bushing clearances exceed

the allowable value, the bushings must be re-

newed. The allowable values for backlash and

bushing clearances should be obtained from the

instruction manual for the engine involved.

Usually, a broken or chipped gear must be

replaced. Care should be exercised in determin-

ing whether a pitted gear should be replaced.

BLOWER ROTOR GEARS

One of the most important parts of a root type

blower is the set of gears that drive and syn-

chronize the two rotors. Satisfactory operation

depends on the condition of these gears.

Worn gears are found by measuring the

backlash of the gear set. Gears with a greater

backlash than specified in the applicable technical

manual are considered to be excessively worn and,

if not replaced, will eventually cause extensive

damage to the entire blower assembly.

A certain amount of gear wear is to be

expected, but scored and otherwise damaged rotor

lobes resulting from excessively worn gears are

inexcusable. It is the duty of the engineering force

to inspect the gears and lobes, and to measure the

clearance at frequent intervals. During the inspec-

tion, it will be possible to measure accurately the

values of backlash. These values should be re-

corded. By observing the rate of increase of wear,

it will be possible to estimate the life of the gears

and to determine when it will be necessary to

replace them.

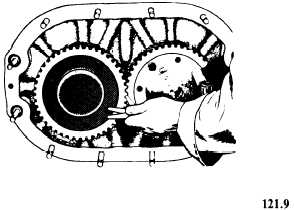

Lobe clearance can be found by determining

the difference of the maximum and minimum

rotor lobe clearance at the same distance from the

center. To find the maximum clearance, hold the

rotors so that there is maximum clearance between

the two rotor lobes. Then, with feeler gages deter-

mine the value of the rotor lobe clearance. (See

figure 3-25.)

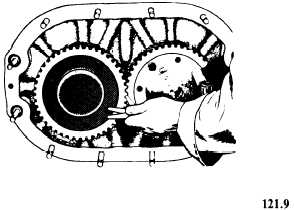

Figure 3-26.—Checking the backlash of blower rotor gears.

The minimum clearance is found in a similar

manner except that rotor lobes are held in such

a position as to take up all slack and backlash.

The difference of the two clearance readings is

the value of the backlash of the rotor lobes. Since

a change in lobe clearance is normally caused by

wear of the gears, the gear clearance must be

checked. The most direct method for checking

gear clearance is by the use of feeler gages. (See

figure 3-26.)

Any gear set which has excessive lash or shows

any sign of fracture must be replaced with a new

set. Since blower drive gears come in matched sets,

gears from different sets must not be

interchanged.

CHAIN MECHANISMS

In some engines, chains are not only used to

drive camshafts and auxiliaries but also to drive

such parts as rotating supercharger valves. Con-

necting links for two types of chains are shown

in figure 3-27. Note that the connecting pins in

one are secured by cotter pins, while the joint pins

shown in the other are riveted.

The principal causes of drive chain failure are

improper chain tension, lack of lubrication,

sheared cotter pins or improperly riveted joint

pins, and misalignment of parts, especially idler

gears.

Chain drives should be checked for any symp-

toms of such difficulties, in accordance with the

instructions in the appropriate engine manual. The

tension should be adjusted as required during

3-39