ENGINEMAN 1 & C

A different type of drive gear mechanism is

used for a four-stroke cycle, V-type gasoline

engine. The camshaft gears are driven through a

train of bevel gears from the crankshaft. This ar-

rangement serves to drive not only the camshaft

but also other accessories, such as a magneto, or

distributor, a fuel pump, and a tachometer. An

additional gear, called the oil and freshwater

pump drive gear, meshes with the crankshaft gear.

The causes of gear failure (improper lubrica-

tion, corrosion, misalignment of parts, torsional

vibration, excessive backlash, wiped gear bearings

and bushing, metal obstructions, and improper

manufacturing procedures) are basically the same

as the causes of similar troubles in other engine

parts. The best method of prevention is to adhere

to the prescribed maintenance procedures and

follow the instructions given in the manufacturer’s

technical manual.

Maintenance and repair of gear trains involve

a thorough check (for scoring, wearing, pitting,

etc.) of the gear shafts, bushings and bearings,

and gear teeth during each periodic inspection.

Be sure that the oil passages are clear, and that

the woodruff keys, dowel pins, and other lock-

ing devices are secured to a tight fit in order to

prevent longitudinal gear movement. It is essen-

tial that all broken or chipped parts be removed

from the lubrication system before new gears are

installed.

An engine must not be barred over while the

camshaft actuating gears are removed from the

train. Should the engine be barred over, there is

75.239

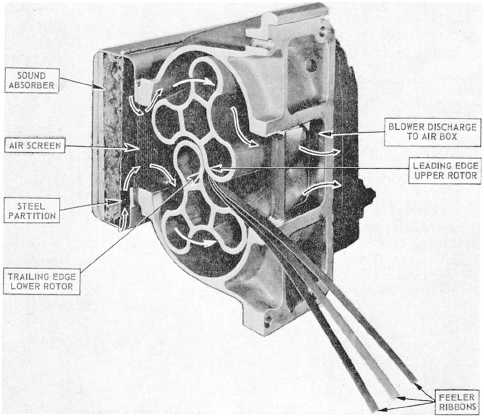

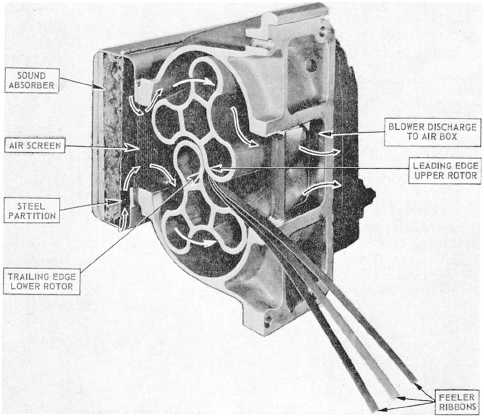

Figure 3-25.—Checking clearance of positive displacement blower lobes.

3-38