ENGINEMAN 1 & C

This is generally the result of very close oil

clearances and the use of an oil having a viscos-

ity higher than recommended. Early stages of the

loss of lead, due to melting, will be evidenced by

very small streaks of lead on the bearing surface.

loads on the main bearings because of the force

that is necessary to retain correct alignment be-

tween the bearing and the journal.

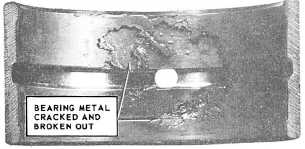

3. Inadequate bond between the bearing metal

and the bearing shell. A poor bond may be

caused by fatigue resulting from cyclic loads, or

it may be the result of defective manufacturing.

A failure due to inadequate bond is shown in

figure 3-20. In such failures, the bearing shell

shows through the bearing surface clearly.

A bent or misaligned connecting rod can be

the cause of a ruined crank-pin bearing. Misalign-

ment between the connecting rod bore and the

piston pin bushing bore is indicated by the crack-

ing of the bearing material at the opposite ends

of the upper and lower-bearing shell. An indica-

tion of a bent connecting rod is heavy wear or

scoring on the piston surface.

4. Out-of-round journals due to excessive

bearing wear. As the bearings wear, excessive

clearance is created; this leads to engine pounding,

oil leakage from the bearing, reduced flow of oil

to other bearings, and overheating, with the con-

sequent melting of bearing material. To prevent

bearing wear, the journals should be checked for

out-of-roundness. Manufacturers require crank

pins to be reground when the out-of-roundness

exceeds a specified amount, but the amount varies

with manufacturers. Always check the engine

manual for this type of data.

5. Rough spots. Burrs or ridges may cause

grooves in the bearings and lead to bearing failure.

Removal of rough spots is done with a fine oil

stone and a piece of crocus cloth. Be sure to place

a clean cloth beneath the journal to catch all par-

ticles. Apply a coat of clean lubricating oil to the

journal and to the bearing before a bearing is

installed.

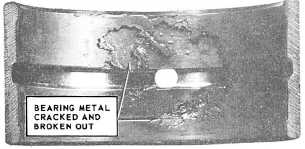

7. Faulty installation, due to negligence or

lack of experience. The paramount factor is

inattention to cleanliness. Hard particles lodge

between the bearing shell and the connecting rod

bore, and create an air space. This space retards

the normal flow of heat and causes localized high

temperatures. Such condition may be further ag-

gravated if the bearing surface is forced out into

the oil clearance spaces and creates a high spot

in the bearing surface. The result of a bearing

failure is illustrated in figure 3-21. Foreign par-

ticles, excessive clearance, or rough surface may

cause poor contact between a bearing shell and

a connecting rod. Poor contact is indicated by the

formation of a gumlike deposit (sometimes re-

ferred to as lacquer or varnish) on the back of

the shell.

6. Misalignment of parts. Misalignment of the

main bearings can be caused by a warped or bent

crankshaft. Such misalignment imposes heavy

Bearing failures may result from improper fit

of the shell to the connecting rod. If the locking

lip of a bearing does not fit properly into the recess

of the bearing housing, distortion of the shell and

failure of the bearing results.

121.5

121.4

Figure 3-20.—Bearing failure due to inadequate bond.

Figure 3-21.—Bearing failure resulting from wiping and

excessive temperatures.

3-34