needle valve even though it has previously been

done at the factory or repair facility. This adjust-

ment must be made with the governor installed

and controlling an engine with a load. If this is

not done, high overspeeds and low underspeeds

after load changes will result and the return to

normal speeds will be slowed. Maintenance and

repair of each unit must be in accordance with

the manufacturer’s maintenance manual and the

PMS.

NOTE: When governor troubles are

suspected, before performing any maintenance or

adjustments, always disconnect the governor fuel

rod end from the fuel control rack and ensure that

there is no sticking or binding of the rack. This

procedure is necessary to determine if the trou-

ble is actually in the governor.

The chart in table 3-1 lists some of the

probable causes of trouble which are common to

most hydraulic governors. This chart should be

used for training purposes only; it must NOT be

used to troubleshoot a governor. Always use the

applicable manufacturer’s instruction manual for

troubleshooting. Following are the definitions of

the terms used in the chart.

HUNT: A rhythmic variation of speed which

can be eliminated by blocking the fuel linkage

manually, but which will reappear when returned

to governor control.

SURGE: A rhythmic variation of speed always

of large magnitude which can be eliminated by

blocking the fuel linkage and which will not reap-

pear when returned to governor control unless the

speed adjustment of the load changes.

JIGGLE: A high frequency vibration of the

governor fuel rod end or engine linkage. Do not

confuse jiggle with normal regulating action of

the governor.

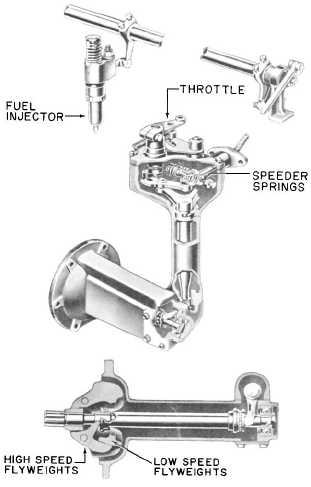

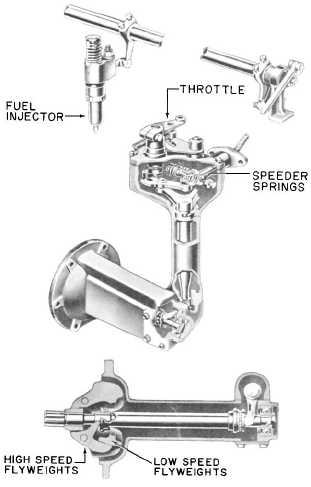

Mechanical Governors

Mechanical governors used in the Navy are

generally of the spring-loaded flyball type. All

mechanical governors have a speed droop. This

means that as the load is increased at a constant

throttle setting, the speed of the engine will drop

or droop slightly, rather than remain constant.

Consequently, mechanical governors are never

used where absolute constant speeds are necessary.

There are several types of mechanical gover-

nors. Two of the most common types are used

on GM 71 engines. One type, known as the

constant-speed governor, is used on generator sets

and is designed to hold the speed of the engine

at a predetermined operating speed. The other

type is similar in construction and is used primar-

ily for propulsion engines. It has a throttle plate

so designed that speeds intermediate between idl-

ing and full speeds may be obtained by manual

adjustment. The following description applies to

both types of governors. Do note, however, that

on the constant-speed governor, there is no buf-

fer spring adjustment.

In the idling speed range, control is effected

by centrifugal force of two sets of flyweights

(figure 3-15), large and small, acting against a light

Chapter 3—ENGINE MAINTENANCE

121.22

Figure 3-15.—GM mechanical governor.

3-23