CHAPTER 3

INTERNAL COMBUSTION ENGINES

This chapter is designed to help you understand the

maintenance and repair of internal combustion engines.

You as an EN2 should be able to describe the basic

procedures used to test and repair diesel engines. Also,

you should be able to identify the procedures used to

troubleshoot diesel and gasoline engines. This chapter

will cover the general procedures used to repair and

overhaul gasoline engines; the procedures used to

inspect, test, and repair jacking gear; and the procedures

used to troubleshoot and repair fuel and oil purifiers.

To help ensure that an engine will operate

efficiently, you must follow its preventive maintenance

schedule. By following the preventive maintenance

schedule, you will reduce engine casualties and help the

engine achieve its normal number of operating hours

between overhaul periods.

When you must finally perform an engine repair or

overhaul, take the following precautions:

l Plan the work in definite steps, so you can

perform it smoothly.

l Have the necessary tools and parts on hand

before you begin a repair or overhaul.

l Have the necessary forms ready to record the

clearances, dimensions, and other vital measurement

readings that must be kept as part of the engine’s history.

l Always check precision measuring instruments

before you use them; then recheck your readings. The

first reading may not be correct.

l Keep the work area clean. Do not allow oil to

accumulate on the deck or on the tools. Place the tools

or parts neatly away from the immediate area.

The test, maintenance, and repair procedures

presented in this chapter are general in nature. The

specific procedures vary with different engines. Before

you begin a maintenance or repair procedure, consult

the manufacturer’s technical manual or the equipment’s

preventive maintenance schedules. They are valuable

sources of information on tests, maintenance, and

repairs.

INSPECTING AND TESTING THE

ENGINE FRAME OR BLOCK

Before you begin an inspection or test, make sure

the outside of the engine is cleaned thoroughly. This will

help you spot cracks, leaks, and other problems more

easily than if the engine is dirty. By cleaning the engine,

you will also help prevent dirt and other contaminants

from entering and damaging parts and accessories of the

engine.

Some of the inspections and tests you may perform

are listed in the following sections.

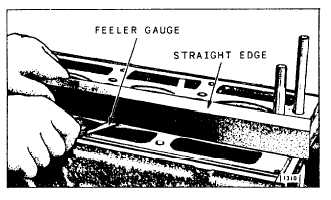

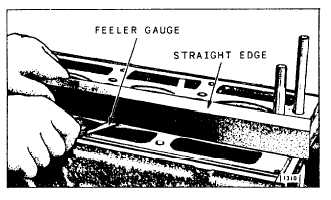

VISUAL INSPECTIONS

Inspect the top surface of the cylinder block, the top

and bottom crankcase flanges, and the oil pan for

warpage. You can use a straightedge, a feeler gauge, and

a good light. Figure 3-1 illustrates how to use a

straightedge and a feeler gauge to check the top surface

of the cylinder block Compare your measurements to

the manufacturer’s specifications to determine if the

surface is warped.

Visually inspect the cylinder block for cracks,

breaks, or other damage.

MEASUREMENTS

Visually inspect the engine block’s bolts to

determine if they are bent, broken, or worn.

Figure 3-1.—Checking the top surface of a typical cylinder block.

3-1