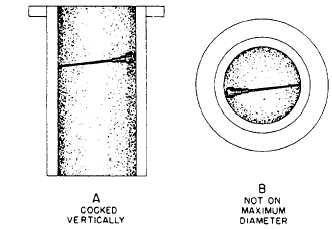

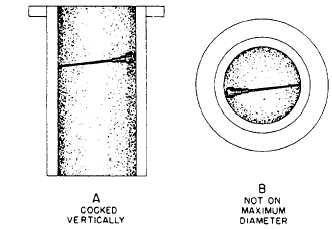

Figure 3-7.—Errors to avoid when taking liner measurements.

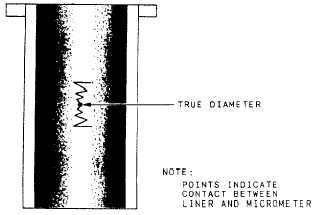

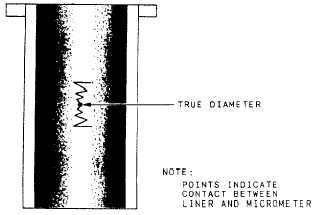

Figure 3-8.—Trace of caliper end when determining the true

diameter of a liner.

practice for two persons to take the liner measurement;

then any discrepancy between the two sets of readings

can be rechecked.

Causes

Excessive or abnormal wear of cylinder liners may

be caused by insufficient lubrication, dirt, improper

starting procedures, or low cooling water temperature.

The lubricating system must be carefully

maintained in proper working order. The method of

cylinder liner lubrication varies with different engines.

The proper grade of oil, according to engine

specifications, should be used

The engine must not be operated in a dirty condition.

The air box, crankcase, and manifold should be cleaned

and maintained in a clean condition, to avoid cylinder

wear and scoring. (Attention to the air cleaner, oil filters,

and oil centrifuge are the best precautions against the

entrance of dirt into the engine.)

Improper starting procedures will cause excessive

wear on the liners and pistons. When an engine is first

started, some time may elapse before the flow of

lubricating oil is completed; also, the parts are cold and

condensation of corrosive vapors is accelerated

accordingly. These two factors (lack of lubrication and

condensation of corrosive vapors) make the period

immediately after starting a critical time for cylinder

liners. If an independently driven oil pump is installed,

it must be used to prime the lube oil system and build

up oil pressure before the engine is started The engine

should not be subjected to high load during the warm-up

period. Follow the manufacturer’s instruction manual

concerning warm-up time and load application for the

engine concerned

The cooling water of an engine should always be

maintained within the specified temperature ranges. If

the temperature is allowed to drop too low, corrosive

vapors will condense on the liner walls.

Repairs

Cylinder liners worn beyond the maximum

allowable limit should be replaced. You will find the

maximum allowable wear limits for engines in the

appropriate manufacturer’s technical manual or the

Diesel Engine Wear Limit Chart available from the

Naval Sea Systems Command. In the absence of such

specific information, the following wear limits

(established by NAVSEA) apply in general to

1. two-stroke cycle engines with aluminum

pistons: 0.0025 inch per inch diameter,

2. slow-speed engines over l8-inch bore: 0.005

inch per inch diameter, and

3. all other engines: 0.003 inch per inch diameter.

If you must remove a liner, follow the instructions

given on the appropriate maintenance requirement card

(MRC) or in the manufacturer’s technical manual for the

particular type of engine. Figure 3-9 illustrates the

method generally used to remove a cylinder liner.

To remove the cylinder liner, proceed as follows:

1. Drain the water from the engine.

2. Remove the cylinder head.

3. Remove the piston(s).

3-6