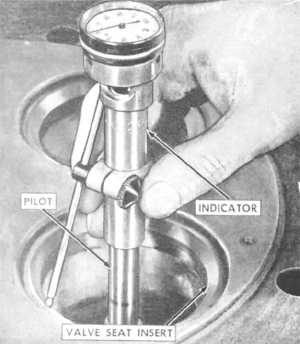

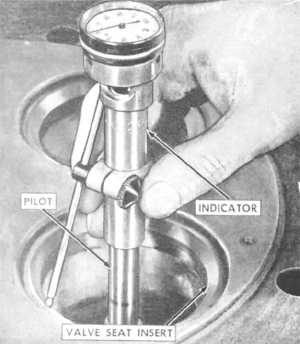

In any valve reconditioning job, the valve seat must be

concentric with the valve guide. You can determine the

concentricity with a dial indicator, as shown in figure

3-12.

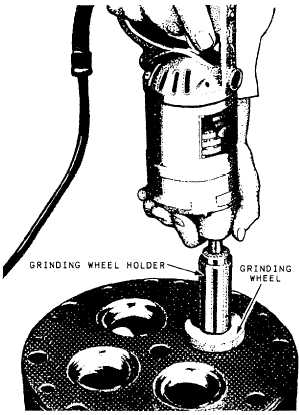

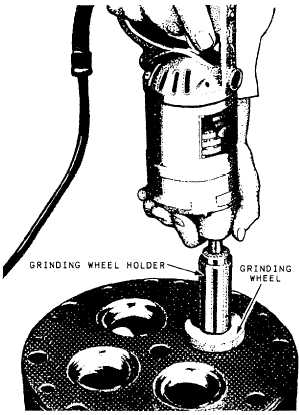

If you must grind a valve seat, hold hand grinding

to a minimum and never use it in place of machine

grinding, in which a grinding stone is used to refinish

the seat (fig. 3-13). Grind the seat a few seconds at a

time until it is free of pits. Check the seat after each cut.

The primary objection to hand grinding the valve to

the seat is that a groove or indentation may be formed

in the valve face. Since the grinding is done when the

valve is cold, the position of the groove with respect to

the seat is displaced as the valve expands slightly when

the engine is running. This condition is illustrated

(greatly exaggerated) in figure 3-14. Note that when the

valve is hot, its ground surface does not make contact at

all with the ground surface of the seat. Therefore, hand

grinding should be used only to remove slight pitting or

as the final and finishing operation in a valve

reconditioning job.

Some valves and seat are not pitted sufficiently to

require replacement but are pitted to such an extent that

hand grinding would be unsatisfactory. Such valves may

be refaced on a lathe (fig. 3-15), and the valve seats may

be reseated by power grinding equipment (fig. 3-13).

Figure 3-12.—Determining concentricity of the valve seat with a

dial indicator.

Figure 3-13.—Machine grinding a valve seat.

Normally, these operations are done at a repair base or

naval shipyard.

A valve head that is excessively reground to such an

extent that its edge is sharp, or almost sharp, will soon

burn. A sharp edge cannot conduct the heat away fast

enough to prevent burning. This is the factor that limits

the extent to which a valve may be refaced.

BROKEN VALVE SPRINGS

Broken valve springs cause excessive valve noise

and may cause erratic exhaust gas temperatures. The

actual breaking of the valve springs is not always the

most serious consequence. Actions following the

breaking cause the most serious damage to the engine.

When a spring breaks, it may collapse just enough to

allow the valve to drop into the cylinder, where it may

be struck by the piston. In addition, the valve stem locks

or keepers may release the valve and allow it to drop

into the cylinder, causing severe damage to the piston,

cylinder head, and other nearby parts.

You can take a number of precautions to prevent or

minimize corrosion and metal fatigue, which cause

valve springs to break Be reasonably careful when you

3-10