The principal cause of burned exhaust valves is

small particles of carbon that lodge between the valve

head and the valve seat. These particles come from

incomplete combustion of the fuel or oil left by the

piston rings in the cylinder. The particles hold the valve

open just enough to prevent the valve head from

touching the valve seat. The valve is cooled by several

means, including its contact with the valve seat. When

carbon particles prevent contact, the heat normally

transferred from the valve head to the seat remains in

the valve head. The valve seat seldom burns because the

water jackets surrounding the seat usually provide

enough cooling to keep its temperature below a

dangerous point.

When cleaning carbon from cylinder heads, remove

all loose particles from the crevices; be extremely

careful that you do not nick or scratch the valve or seat.

Removing the valves from the engine will make it easier

to clean the passages and remove the carbon deposits

from the underside of the valve heads.

Check the tappet clearance adjustments at frequent

intervals to be certain they are correct and that the

locking devices are secure. The adjustment of valve

clearances is discussed later in this chapter.

Most engines are equipped with valve seat inserts

made of hard, heat-resisting, alloy steel. Occasionally, a

seat will crack and allow the hot gases to leak, burning

both the insert and the valve. Sometimes a poor contact

between the valve seat insert and the counterbore

prevents the heat from being conducted away, and the

high temperatures deform the insert. When this occurs,

both the seat and the valve will burn; the seat insert must

be rep1aced.

LOOSE VALVE SEATS

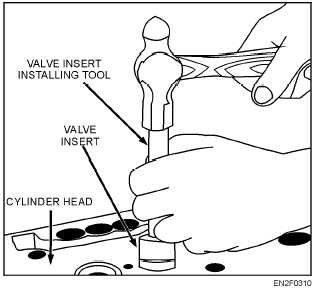

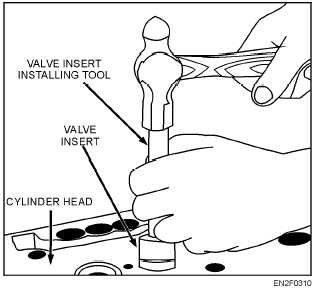

You can avoid causing loose valve seats only by

installing them properly. Clean the counterbore

thoroughly to remove all carbon before shrinking in an

insert. Chill the valve seat with dry ice and place the

cylinder head in boiling water for approximately 30

minutes; then drive the insert into the counterbore with

a valve insert installing tool, as illustrated in figure 3-10.

Never strike a valve seat directly. Do the driving

operation quickly, before the insert reaches the

temperature of the cylinder head

When replacing a damaged valve with a new one,

inspect the valve guides for excessive wear. If the valve

moves from side to side as it seats, replace the guides.

Figure 3-10.–Driving a valve iusert into the cylinder head

counterbore.

PITTING

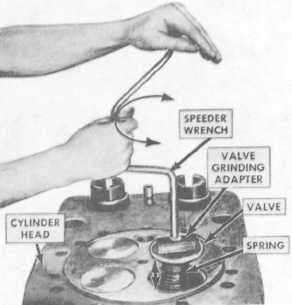

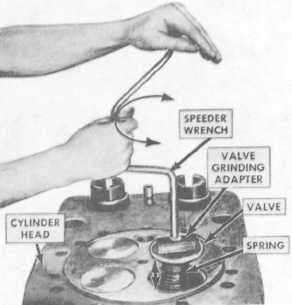

If the valve seat is secured firmly in the counterbore

and is free of cracks and burns, you may remove slight

damage such as pitting by hand grinding (fig. 3-11).

Generally, you will use prussian blue to check the valve

and valve seat, but if this is not available, use any thin

dark oil-based paint. Allow the valve to seat by dropping

it on the valve seat from a short distance. If the surfaces

fail to make complete contact, regrinding is necessary.

75.72

Figure 3-11.–Hand grinding a valve and valve seat.

3-9