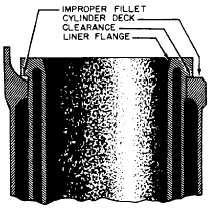

Figure 3-3.—Improperly seated cylinder liner.

improper fillet, grind it down until the lower surface of

the flange seats properly on the mating surface of the

cylinder deck.

An oversized sealing ring may cause improper

positioning of the liner. As the sealing ring is

overcompressed, the rubber loses its elasticity and

becomes hard, which may cause the liner to become

distorted.

Use feeler gauges to check the clearance between

the mating surfaces. If the manufacturer’s technical

manual specifies the distance from the cylinder deck to

the upper surface of the liner flange, use this dimension

to check on the seating of the liner.

Obstructions in the combustion chamber may be

destructive not only to the liner but also to the cylinder

head and other parts.

Erosion and corrosion may take place in a few

isolated spots and weaken a liner sufficiently to cause

cracks.

Repairs

Replacement is the only satisfactory means of

correcting cracked, broken, or badly distorted cylinder

liners.

SCORED CYLINDER LINERS

Scored cylinder liners may become scored

(scratched) by several means. These scratches degrade

the engine’s performance and require some type of

repair.

Scored cylinder liners may be caused by broken

piston rings, a defective piston, improper cooling,

improper lubrication, or the presence of foreign particles

or objects. Dust particles drawn into an engine cylinder

will mix with the oil and become an effective but

undesirable lapping compound that may cause extensive

damage. The importance of keeping the intake air clean

cannot be overemphasized.

Another precaution you should take is to make sure

that when you replace a cylinder head, you leave no

metal chips, nuts, bolts, screws, or tools in the cylinder.

Causes

Scoring may be in the form of deep or shallow

scratches in the liner surface. With most liner scoring,

there will be corresponding scratches on the piston and

piston rings. The symptoms of scoring may be low firing

or compression pressure and rapid wear of piston rings.

The best method for detecting scoring is visual

inspection through liner ports, through the crankcase

housing with pistons in their top position, or when the

engine is disassembled.

Badly worn pistons and rings may cause scoring

because blowby of combustion gases increases the

temperature of the liner and may reduce the oil film until

metal-to-metal contact takes place. Inspect the pistons

and rings carefully. A piston with a rough surface (such

as one that has seized) will score the liner.

Scoring as a result of insufficient lubrication or dirt

in the lubricating oil can be prevented if lubricating

equipment (filters, strainers, and centrifuges) is

maintained properly. Lube oil must be purified

according to required procedures.

Repairs

Ship’s force personnel normally do not repair scored

liners; they replace them with spare liners. When

necessary, liners with minor scoring may be kept in

service, if the cause of scoring is eliminated and the

minor defects can be corrected. The surface of the liner

must be inspected carefully, especially in the region next

to the ports, for any burrs, projections, or sharp edges

that will interfere with piston and ring travel. Most

projections can be removed by handstoning, using a fine

stone. Figure 3-4 shows a liner before and after the ports

were stoned.

EXCESSIVELY WORN LINERS

Over a period of time, cylinder liners become worn

simply because of engine operation. The best method of

finding excessive wear is to take measurements of the

cylinder liner with an inside micrometer caliper. Two

3-4