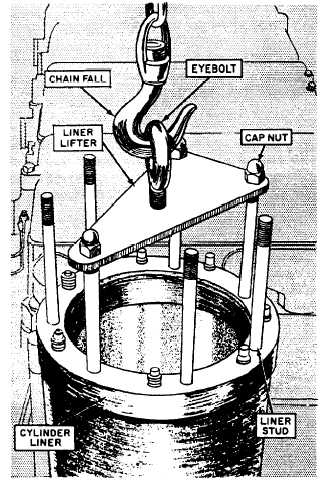

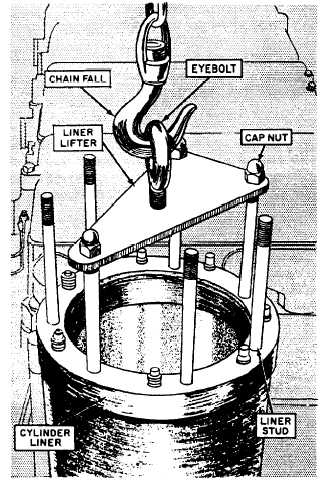

Figure 3-9.—Removing a cylinder liner.

4. Attach the special liner puller to the liner studs

and tighten the nuts by hand. (The nuts must be hand

tightened; if a wrench is used, the threads on both the

nuts and the studs may be damaged.)

5. Attach the hook of the chain fall and pull slightly

until the liner breaks free (fig. 3-9). If the liner fails to

break loose immediately, apply pressure at the bottom

of the liner. To do this, place a block of wood on the

crankshaft throw, and force it up against the liner by

rotating the turning gear.

6. Lift the liner up until it clears the top of the

engine block and remove it to a safe place. You may need

to rotate the liner slightly while removing it from the

engine block.

INSPECTING, TESTING, AND

REPAIRING CYLINDER HEADS

Conditions requiring repair of a cylinder head are

similar to those for cylinder liners and can be grouped

under cracks, corrosion, distortion, and fouling.

CRACKS

The symptoms of a cracked cylinder head are the

same as those of a cracked liner. Cracks in cylinder

heads are best located by either visual inspection or

magnetic powder inspection. On some types of engines,

a defective cylinder can be located by bringing the

piston of each cylinder, in turn, to top dead center and

applying compressed air. When air is applied to a

damaged cylinder, a bubbling sound indicates leakage.

When the cylinder head is removed from the engine,

it can be checked for cracks by the hydrostatic test used

on cylinder liners equipped with integral cooling

passages.

Cracks generally occur in cylinder heads on the

narrow metal sections between such parts as valves and

injectors. The cracks may be caused by adding cold

water to a hot engine, by restricted cooling passages, by

obstructions in the combustion space, or by improper

tightening of studs.

Aboard ship, cracked cylinder heads usually must

be replaced. It is possible to repair them by welding, but

this process requires special equipment and highly

skilled personnel normally found only at repair

activities.

CORROSION

Burning and corrosion of the mating surfaces of a

cylinder head may be caused by a defective gasket.

Although regular planned maintenance ordinarily

prevents this type of trouble, burning and corrosion may

still take place under certain conditions. When corrosion

and burning occur, there may be a loss of power due to

combustion gas leakage out of or water leakage into the

combustion space. Other symptoms of leakage may be

(1) hissing or sizzling in the head where gases or water

may be leaking between the cylinder head and the block,

(2) bubbles in the cooling water expansion tank sight

glass, or (3) overflow of the expansion tank.

Gaskets and grommets that seal combustion spaces

and water passages must be in good condition; otherwise

the fluids will leak and cause corrosion or burning of the

area contacted. Improper cooling water treatment may

also accelerate the rate of corrosion.

In general, cylinder heads that are burned or

corroded by gas or water leakage are so damaged that

they must be replaced.

3-7