Whether the causes of broken valve heads are

mechanical deformation or metal fatigue, you must take

every precaution to prevent their occurrence. If a valve

head breaks loose, be sure to make a thorough inspection

of all associated parts before you replace the valve.

ROCKER ARMS AND PUSHRODS

The principal trouble that rocker arms and pushrods

may have is WEAR, which may occur in bushings, or

on the pads, end fittings, or tappet adjusting screws.

Worn rocker arm bushings are usually caused by

lubricating oil problems. A bushing with excessive wear

must be replaced. When installing a new bushing, you

usually need to use a reamer for the final fit.

Wear at the points of contact on a rocker arm is

generally in the form of pitted, deformed, or scored

surfaces. Wear on the rocker arm pads and end fittings

is greatly accelerated if lubrication is insufficient or if

there is excessive tappet clearance. Pushrods are usually

positioned to the cam followers and rocker arms by end

fittings. The pads are the rocker arm ends that bear the

valve stem or valve stem cap. When the tappet clearance

is excessive, the rods shift around, greatly increasing the

rate of wear of both the rocker arm and the rod contact

surfaces. Worn fittings necessitate the replacement of

parts. Continued use of a poor fitting and worn pushrod

is likely to result in further damage to the engine,

especially if the rod should come loose.

Worn tappet adjusting screws and locknuts usually

make maintaining proper clearances and keeping the

locknuts tight very difficult. Wear of the adjusting

screws is usually caused by loose locknuts, which allow

the adjusting screw to work up and down on the threads

each time the valve is opened and closed. To prevent this

wear, tighten the locknuts after each adjustment and

check the tightness at frequent intervals.

If the threads are worn, replace the entire rocker

arm. Do NOT attempt to repair the threads or to use a

new tappet adjusting screw except in cases of

emergency.

The adjustment of the rocker arm assembly consists

chiefly of adjusting the tappets for proper running

clearance. The valve clearance for both intake and

exhaust valves should be readjusted after overhaul. The

procedure for adjusting the rocker arm tappets of a

typical 4-stroke cycle engine is as follows:

1. Rotate the crankshaft and move the piston whose

tappets you plan to adjust to top dead center of the

compression stroke.

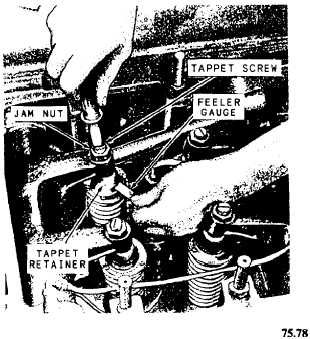

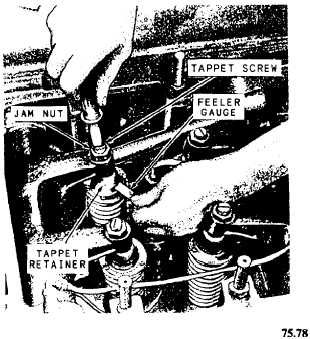

2. Loosen the locknut (jam nut) on the tappet

screw, and insert a screwdriver in the slot of the screw.

3. Insert a feeler gauge of the proper thickness

between the tappet bearing and the end of the valve stem.

4. Tighten the tappet screw (fig. 3-16) until the

feeler gauge will just slide freely between the bearing

and the valve stem.

5. lighten the jam nut and check the clearance. The

jam nut has a tendency to increase the clearance when

tightened; therefore, ALWAYS check the clearance after

you tighten the jam nut.

The procedure just outlined is a preliminary, or cold

engine check. Check and readjust the clearance, if

necessary, after the engine has been in operation for a

short time and has reached the normal operating

temperature. The manufacturer’s technical manual will

give the recommended valve clearances for a specific

make and model of engine and will indicate whether the

clearances given apply to cold or hot engines.

CAM FOLLOWERS AND LASH

ADJUSTERS

Regardless of the type of cam follower, wear is the

most common trouble. Worn rollers will usually develop

holes or pit marks in the roller surfaces. The mushroom

type may develop a shallow channel when the cam

Figure 3-16.—Adjusting valve clearance.

3-12