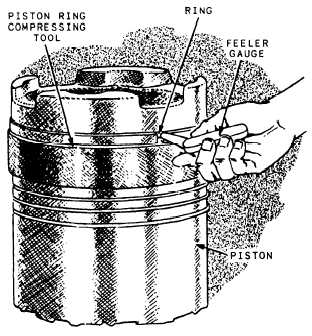

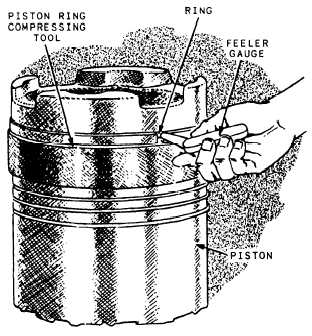

Figure 3-22.–Checking ring gap clearance.

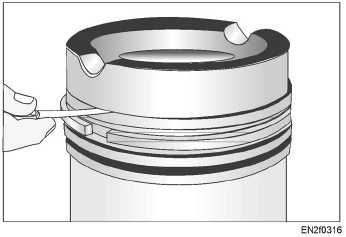

been installed, check the ring-to-land clearance. (See

fig. 3-23.) If the clearance is too small, the ring may

bind or seize, allowing improper sealing and blowby to

occur. If the clearance is excessive, the ring may flutter

and break itself or the piston land.

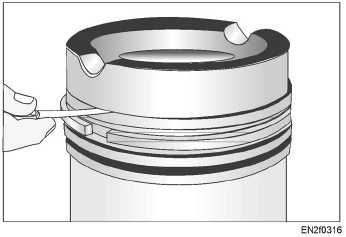

After you have properly installed all the rings, coat

the entire assembly with oil, then insert it into the

cylinder bore. Position the rings so the gap of each

successive ring is on an alternate side and the gaps are

in line with the piston pin bosses. On large engines, use

a chain fall to hold the piston assembly in position as

you lower it into the cylinder. (See fig. 3-24.)

Figure 3-23.–Checking ring groove side clearance.

75.56

Figure 3-24.–Installing a piston in a cylinder bore with a

funnel-type ring compressor.

When a piston is being inserted into a cylinder, the

piston rings must be compressed evenly. Special

funnel-type tools, similar to the one shown in figure 3-24

are usually provided for this purpose. Another type of

ring compressing tool is a steel band that can be placed

around the ring and tightened.

PISTONS

Trunk-type pistons are subject to forces such as gas

pressure, side thrust, inertia, and friction. These forces,

together with overheating and the presence of foreign

matter, may cause troubles such as undue piston wear,

crown and land dragging, cracks, piston seizure,

clogged oil holes, and piston pin bushing wear.

Excessive Piston-to-Liner Clearance

Symptoms of excessive clearance between a piston

and its cylinder are piston slap and excessive oil

consumption. Piston slap occurs just after top dead

center and bottom dead center, as the piston shifts its

thrust from one side to the other. As the cylinder taper

increases with wear, oil consumption increases. Since

taper causes the rings to flex on each stroke of the piston,

excess ring wear occurs, allowing lube oil to pass and

3-16