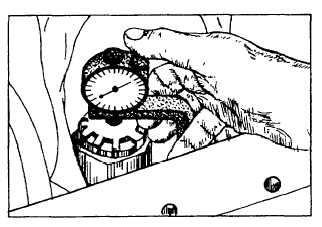

Figure 3-31.—Gauge used for measuring bolt elongation.

Figure 3-32.—Measuring bolt elongation.

and figure 3-32 illustrates the gauge in use. The proper

elongation is listed in the engine manufacturer’s

technical manual.

After you reassemble a bearing, always bar or jack

over the engine by hand through several revolutions.

Check to see that all reciprocating and rotating parts

function freely and that the main and connecting rod

bearings do not bind on the crankshaft. Turn larger diesel

engines over first by the manual jacking gear provided

and then by the engine starting system.

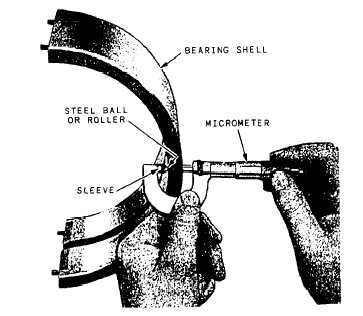

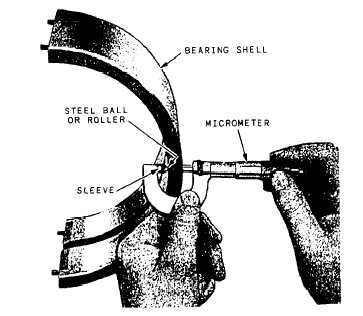

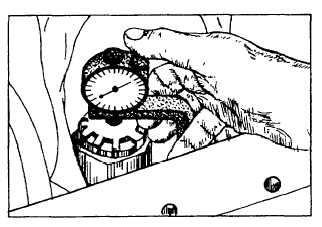

Figure 3-33.—Measuring bearing shell thickness.

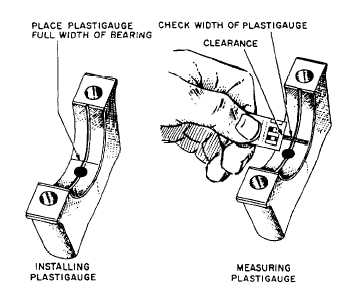

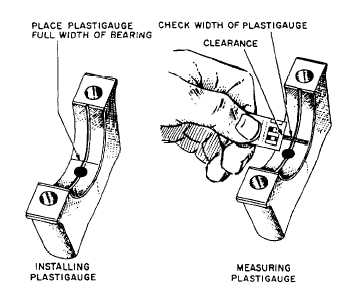

Figure 3-34.—Checking bearing clearance with a Plastlgage.

MEASURING BEARING CLEARANCES

Do not use leads, shim stock, or other such items to

determine clearance of precision bearings. These items

may seriously damage the soft bearing material. Instead,

use a micrometer fitted with a spherical seat to measure

the thickness of bearing shells. Place the spherical tip

against the inside of the bearing shell to obtain an

accurate reading and to prevent injury to the bearing

material. Figure 3-33 shows a micrometer caliper fitted

with a steel ball for measuring bearing thickness.

An alternate method for determining clearance is

with a Plastigage (fig. 3-34). The Plastigage will not

3-21