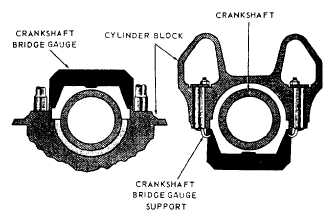

Figure 3-35.—Crankshaft bridge gauge.

leave an impression in the soft bearing metal because

the gauge material is softer than the bearing. To use this

method, place a length of the Plastigage of proper gauge

across the bearing. Then, assemble the bearing cap and

tighten it in place. DO NOT TURN the crankshaft, as

that will destroy the Plastigage. After you install and

properly fasten the bearing cap, remove it. Compare the

width of the crushed Plastigage with the Plastigage chart

to determine the exact clearance.

You must take measurements at specified intervals,

usually at every overhaul, to establish the amount of

bearing wear. Also take a sufficient number of

crankshaft journal diameter measurements at suitable

points to determine possible out-of-roundness.

With some types of engines, a crankshaft bridge

gauge (fig. 3-35) is used to check the wear of the main

bearing shells. To use the gauge, place it on the

crankshaft and measure the clearance between the

bridge gauge and the shaft with a feeler gauge. Any

variation between the measured clearance and the

correct clearance (usually stamped on the housing of

each bearing) indicates that main bearing wear has

occurred. The maximum limits of wear are listed in the

manufacturer’s technical manual. Some engine

manufacturers recommend that bridge gauge readings

be taken at every overhaul in conjunction with crank

web deflection measurements.

The important point to remember is that if you

cannot overhaul an engine due to lack of space,

manpower, or expertise, you may request outside help

by using an OPNAV Form 4790/2K. This form, when

used as a work request, will be sent to a ship intermediate

maintenance activity (SIMA). The SIMA will then

accept or reject the work request. If the work request is

accepted, the SIMA will order all repair parts, overhaul

the engine, and perform an operational test according to

the manufacturers’ technical manuals and the NSTM,

chapter 233.

As stated earlier in this section, maintenance cards,

manufacturers’ maintenance manuals, and various other

instructions discuss repair procedures in detail.

Therefore, this chapter will be limited to general

information on some of the troubles encountered during

overhaul, the causes of such troubles, and the methods

of repair.

TROUBLESHOOTING

INTERNAL-COMBUSTION ENGINES

The

procedures

for

troubleshooting

internal-combustion engines are somewhat similar for

both diesel and gasoline engines. In many instances, the

information that follows will apply to both types of

engine. However, it also discusses principal differences.

Since most of the internal-combustion engines used by

the Navy are diesel, the following sections deal

primarily with this type of engine.

This chapter is concerned with troubles that occur

both when an engine is starting and running. The

troubles are chiefly the kind that can be identified by

erratic engine operation, warnings by instruments, or

inspection of the engine parts and systems and that can

be corrected without major repair or overhaul. There is

also a section devoted to the systems of the gasoline

engine that are basically different from those of the

diesel engine.

Keep in mind that the troubles listed here are general

and may or may not apply to a particular diesel engine.

When you work with a specific engine, check the

manufacturer’s technical manual and any instructions

issued by the Naval Sea Systems Command.

An engine may continue to operate even when a

serious casualty is imminent. However, symptoms are

usually present. Your success as a troubleshooter

depends partially upon your ability to recognize these

symptoms when they occur. You will use most of your

senses to detect trouble symptoms. You may see, hear,

smell, or feel the warning of trouble to come. Of course,

common sense is also a requisite. Another factor in your

success as a troubleshooter is your ability to locate the

trouble once you decide something is wrong with the

equipment. Then, you must be able to determine as

rapidly as possible what corrective action to take. In

3-22