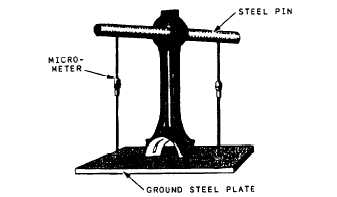

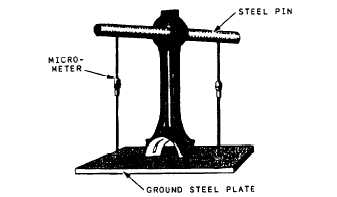

Figure 3-28.—Checking the alignment of a connecting rod.

REPAIRING CRANKSHAFTS AND

JOURNAL BEARINGS

The repair of crankshafts and bearings varies

depending on the extent of damage. There is no doubt

about the necessity for replacing such items as broken

or bent crankshafts. Out-of-round journals may be

reground and undersize bearing shells may be installed,

but this requires personnel skilled in the use of precision

tools. If a new shaft is available, it should be installed

and the damaged shaft should be sent to a salvage

reclamation center. Under certain conditions, scored

crankshaft journals or damaged journal bearings may be

kept in service if proper repair is performed.

Repair of SCORED JOURNALS depends on the

extent of scoring. If a crankshaft has been overheated,

the effect of the original heat treatment will have been

destroyed. In this case, the crankshaft should be

replaced.

If journal scoring is only slight, you can use an

oilstone for dressing purposes if you take precautionary

measures with respect to abrasives during the procedure.

During the dressing operation, plug all oil passages

within the journal and those connecting the mainbearing

journal and the adjacent connecting rod journal.

In the dressing procedure, use a fine oilstone,

followed with crocus cloth, to polish the surface. After

dressing journals, always wash them with diesel oil.

This procedure must include washing the internal oil

passages as well as the outside journal surfaces. Some

passages are large enough to accommodate a cleaning

brush; smaller passages can be cleaned by blowing them

out with compressed air. Always dry the passages by

blowing compressed air through them.

NEVER STOW A CRANKSHAFT OR BEARING

PART ON ANY METAL SURFACE. When you remove

a shaft from an engine, place it on a wooden plank with

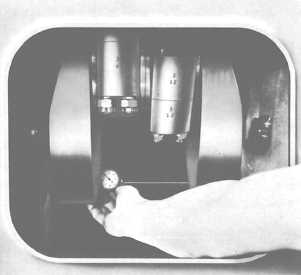

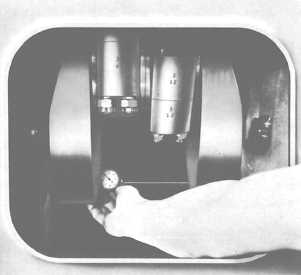

Figure 3-29.—Using a strain or deflection gauge between crank

webs.

all journal surfaces protected. If the shaft is to be

exposed for some time, protect each journal surface with

a coating of heavy grease. Always place bearings on

wooden boards or clean cloths.

CRANKSHAFT overhaul consists of an inspection,

servicing for scoring and wear, and a determination of

each crank web deflection. Take crank web deflection

readings according to the Planned Maintenance System

(PMS).

A strain gauge, often called a crank web deflection

indicator, is used to take deflection readings. The gauge

is merely a dial-reading inside micrometer used to

measure the variation in the distance between adjacent

crank webs as the engine shaft is barred over. Figure

3-29 shows a strain gauge between crank webs.

When you install the gauge, or indicator, between

the webs of a crank throw, be sure to place the gauge as

far as possible from the axis of the connecting rod

journal. Rest the ends of the indicator in prick-punch

marks in the crank webs. If these marks are not present,

make them so that the indicator can be placed in its

correct position. Consult the manufacturer’s technical

manual for the proper location of new marks.

Readings are generally taken at the four crank

positions: top dead center, inboard, near or at bottom

dead center, and outboard. In some engines, it is possible

to take readings at bottom dead center. In others, the

connecting rod may interfere, making it necessary to

take the reading as near as possible to bottom dead

center without having the gauge come in contact with

the connecting rod. When the gauge is in its lowest

3-19