be burned in the cylinder. This results in the

accumulation of excessive carbon deposits.

Crown and Land Dragging

Pistons and liners may become sufficiently worn to

permit the piston to cock over in the cylinder. This

allows the crown and ring lands to drag on the cylinder

wall. The results of dragging can be determined by

visually inspecting the parts of the piston in question.

Piston Wear

Although piston wear is normal in all engines, the

amount and rate of piston wear depend on several

controllable factors. (The causes of excessive piston

wear, and crown and land dragging, are also the causes

of other piston troubles.)

One of the controllable factors is LUBRICATION.

An adequate supply of oil is essential to provide the film

necessary to cushion the piston and other parts within

the cylinder and prevent metal-to-metal contact.

Inadequate lubrication will not only cause piston wear

and crown and land dragging, but also may cause piston

seizure, and piston pin busing wear.

Lack of lubrication is caused either by a lack of lube

oil pressure or by restricted oil passages. The

pressure-recording instruments usually give warning of

low oil pressure before any great harm results. However,

clogged passages offer no such warnings, and their

discovery depends on the care that is exercised in

inspecting and cleaning the piston and connecting rod

assembly.

Another controllable factor that may be directly or

indirectly responsible for many piston troubles is

IMPROPER COOLING WATER TEMPERATURE.

If an engine is not operated within the specified

temperature limits, lubrication troubles will develop.

High cylinder surface temperatures will reduce the

viscosity of the oil. As the cylinder lubricant thins, it will

run off the surfaces. The resulting lack of lubrication

leads to excessive piston and liner wear. However, if

temperatures are below those specified for operation,

viscosity will be increased, and the oil will not readily

reach the parts requiring lubrication.

Oil plays an important role in the cooling of the

piston crown. If the oil flow to the underside of the

crown is restricted, deposits caused by oxidation of the

oil will accumulate, lowering the rate of heat transfer.

Therefore, the underside of the piston crown should be

thoroughly cleaned whenever pistons are removed

While insufficient and uneven cooling may cause

ring land failure, excessive temperatures may cause

piston seizure; an increase in the rates of oxidation of

the oil, resulting in clogged oil passages; or damage to

piston pin bushings.

Seizure or excessive wear of pistons may be caused

by IMPROPER PIT. New pistons or liners must be

installed with the piston-to-cylinder clearances

specified in the manufacturer’s instruction manual.

PISTON PINS AND SLEEVE BEARINGS OR

BUSHINGS

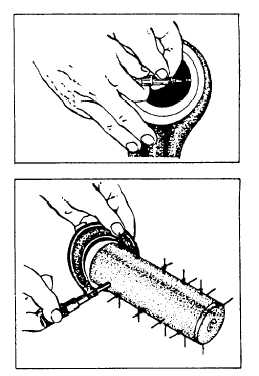

Every time you remove a piston assembly from an

engine, inspect it for wear. Measure the piston pins and

sleeve bearings or bushings with a micrometer, as shown

in figure 3-25, to determine whether wear is excessive.

Do NOT measure areas that do not make contact. Such

areas include those between the connecting rod and

piston bosses and areas under the oil holes and grooves.

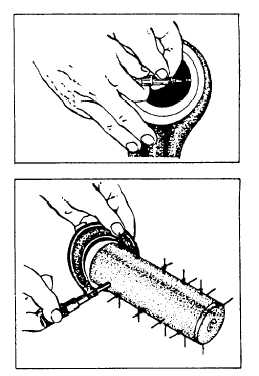

You can press bushings out of the rod with a mandrel

and an arbor press or with special tools, as shown in

figure 3-26. You can also remove bushings by firt

shrinking them with dry ice. Dry ice will also make it

easier to insert the new bushing.

Figure 3-25.—Measuring a piston pin and piston bushing for

wear.

3-17