procedure, comply with all the procedures specified by

the PMS.

complete system. Remember that with any electrical

problem, you will need the help of an Electrician’s Mate,

who is fully trained for electrical work

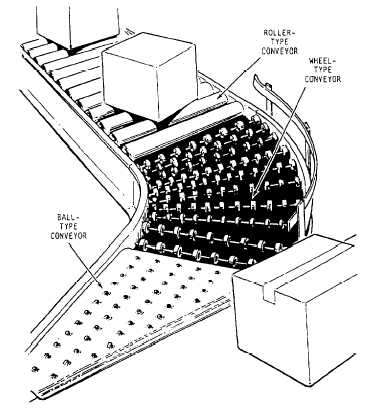

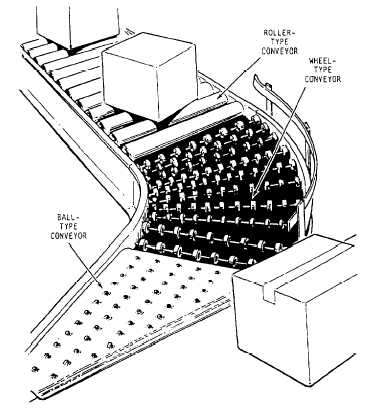

CONVEYORS

The two types of conveyors the Navy uses for

shipboard handling are gravity and powered. This

section will deal with the general concepts of

maintaining, troubleshooting, and repairing the

conveyors within ship’s force capability. When working

on a conveyor, always follow the manufacturer’s

manual or the PMS. For more general information

concerning conveyors, read NSTM, Chapter 572,

“Shipboard Stores and Provision Handling.” Figures

8-7, 8-8, and 8-9 are examples of some conveyors the

Navy uses.

The difficulties most likely to be encountered

during the operation of powered conveyors are not due

to a malfunctioning of the mechanical equipment, but to

the electrical equipment and the related interlocks. The

following list contains common conveyor troubles that

you may experience, the probable causes, and remedies

for each of the troubles listed. The cause for improper

operation is best diagnosed with adequate testing

equipment and a thorough understanding of the

Trouble

Conveyor will

not start.

Conveyor will

not hoist.

Conveyor will

not lower.

Conveyor runs

continuously

when set at

INDEX.

Probable Cause Solution

Power fails.

Determine and

correct cause of

power failure.

Main line fuse is Replace fuse.

blown.

Selector switch

Check and reset

or switches are

selector switches.

improperly set.

Selector switch

Check and reset

or switches are

selector switches.

improperly set.

Loading/unload- Reposition

ing platform is

platform in

set in horizontal

either stowed or

position.

decline position.

Limit switch is

Adjust limit

inoperative.

switch to actuate

when bell crank

passes.

Figure 8-7.—Gravity conveyor.

8-14