SCULLERY EQUIPMENT

You must read the manufacturer’s instruction book

for each machine and become familiar with all its

operating characteristics and its basic design. If

routinely cleaned, descaled, and properly maintained,

scullery machines will not have any problems. But

these procedures must be done on time as specified by

the planned maintenance schedule or by the

manufacturer’s manual. Any necessary repairs and

parts replacement requests must be submitted by the

responsible division on Ship’s Maintenance Action

Form, OPNAV 4790/2K. Following this procedure and

using this form will provide you, as the maintenance

person, a document of repairs and parts that failed.

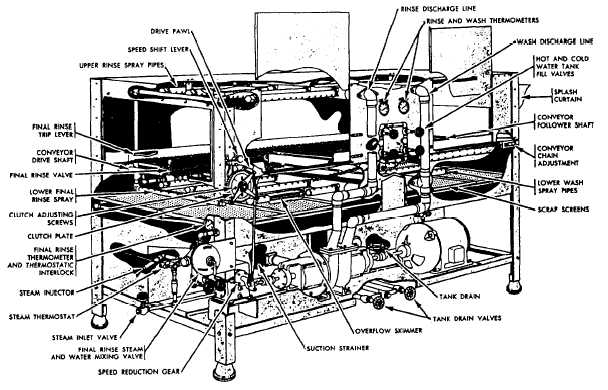

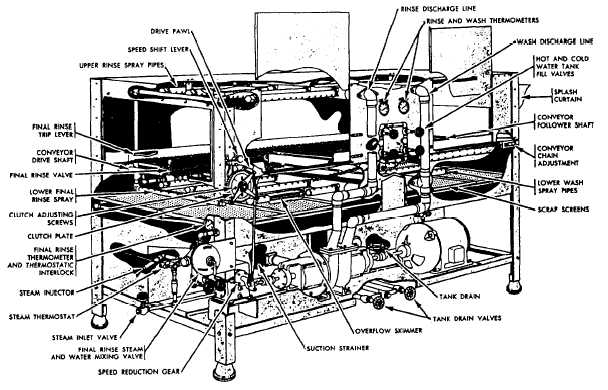

TROUBLESHOOTING

From time to time, you may be called upon to repair

scullery machines that have become defective. Figures

7-5 and 7-6 illustrate the types of scullery machines used

by the Navy. Some common difficulties, the usual

reasons for their occurrence, and possible remedies for

those difficulties are listed in table 7-4.

REPAIRS OR OVERHAULS

Scullery machines must be inspected by the

maintenance personnel according to the PMS schedule.

Listed here are some common inspections,

maintenance, repairs, or overhauls you may encounter

with these machines. You should perform the following:

1. Check the adjustment of tension on the conveyor

chains if the machine is equipped with a conveyor. If

the chain is equipped with lugs, make sure the lugs on

both chains are directly opposite each other.

2. See that the guide sprockets are properly located

on their shaft so that the conveyor chain will ride

properly on the track assembly.

3. Inspect the operation of the doors and make sure

all the counterweights are properly attached and the

doors are held in the open position when raised.

4. Check the operation of thermometers, pressure

gauges, thermostats, and automatic mixing valves or

boosters.

5. Adjust the thermostat so that the machine will

not start up unless the desired temperature is reached.

6. Inspect the pump packing and adjust as

necessary to stop leakage around the pump shaft.

Figure 7-6.—Cutaway view of a double-tank automatic dishwasher.

7-9