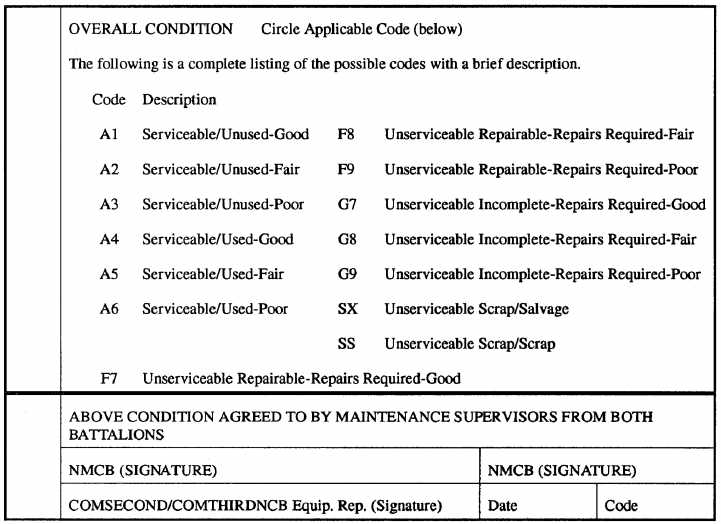

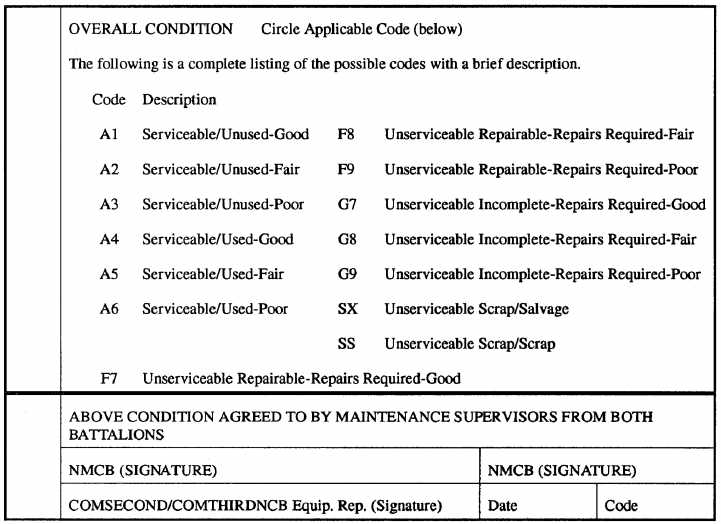

Figure 1-26B.—Equipment Evaluation Inspection Guide (Back)—Continued.

CESE inspections 2 or 3 days before the planned

BEEP completion date, ensuring that all CESE is

processed through the mechanic shop.

Mechanic

inspectors

conduct

BEEP

inspections

using

the

Equipment

Evaluation

Inspection Guide. A safety inspection Equipment

Repair Order (ERO) is developed for all CESE

assigned. Any discrepancies listed on the evaluation

guide is transferred to an ERO for repairs. Maintenance

supervisors determine what repairs can be accomplished

based on the work force, space, and repair parts

available. Additionally, they inspect all maintenance

records, review and account for all maintenance

correspondence, and inventory and inspect all

permanent Alfa company shop equipment. The

maintenance supervisors review all the Equipment

Evaluation Inspection Guides and approve all

Equipment Condition Codes (fig. 1-28) for each CESE.

After the final inspections of all CESE, the

mechanics place NMCB unit identification marking

decals (red-diamond shape for organic equipment and

white-diamond

shape

for

augment

allowance

equipment) in the correct locations. The dispatcher

signs Block 77 of the EROs for customer approval of

all CESE “BEEPed.”

COMSECOND or COMTHIRD equipo reviews

and approves all BEEP equipment evaluation guides

and EROs. At the completion of all Alfa company

inspections, the relieving equipment officer signs the

TAB A as acceptance of the equipment for the

relieving battalion.

LICENSE PROGRAM

A properly administered license program ensures

only thoroughly trained personnel who are physically

1-35