The transportation supervisors should track

the status and location of all CESE and Equipment

Evaluation Inspection Guides. At the end of each

workday,

the

operations

and

maintenance

supervisors request a transportation pool status of all

the CESE that are EO inspected, are on the shop line,

are in the shop, and are turned over with new BEEP

stickers. Additionally, you should track CESE that

has been washed, greased, staged, inspected, and

processed through collateral equipage. Enforcement

of good communication between the yard boss,

dispatchers, cost control, and the EO inspectors

enhances the control of equipment and paper work.

Remember, paper work can be easily misplaced.

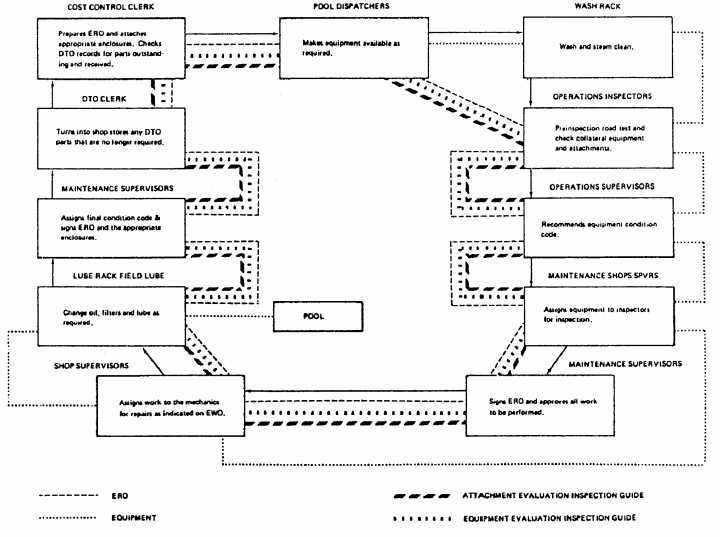

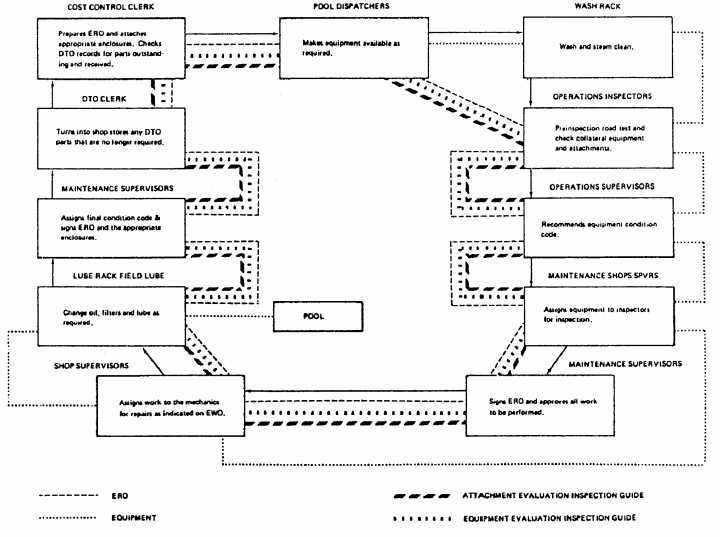

The transportation supervisors must inform

all the Equipment Operators of the BEEP flow chart

(fig. 1-25). The dispatchers should issue the

Equipment Evaluation Inspection Guide (fig. 1-26) to

the EO equipment inspectors for each CESE

inspected along with the Attachment Evaluation

Inspection Guide (fig. 1-27), when required. The EO

inspectors follow the procedures outlined on the

inspection guides, and when completed, take the

CESE to collateral equipage. The collateral equipage

is jointly inspected by each collateral custodian,

noting condition and deficiencies of collateral

equipage for each CESE inspected. Both custodians

must sign the inspection guide. The Equipment

Evaluation Inspection Guides are delivered to the

Alfa company operations supervisors who issue an

Equipment Condition Code (fig. 1-28) for all CESE

inspected by the EOs. The EO inspectors park the

CESE on the shop line and take the paper work to cost

control. The Equipment Operators must complete all

Figure 1-25.—Battalion Equipment Evaluation Program (BEEP) Flow Chart.

1-32