When packing by trucks does not cause damage to

the material, a pile can be smoothed off with a dozer,

and one or more additional layers can be added. Factors

limiting the maximum height are the slope in from the

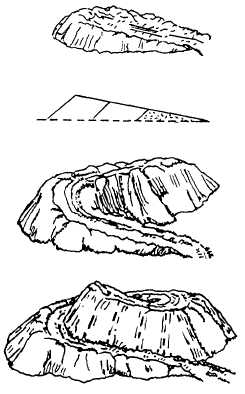

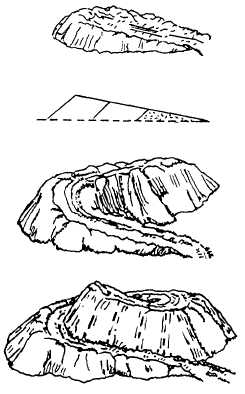

edges and the gradual grade for the truck ramp. Figure

6-13 illustrates the building of a stockpile by backing

trucks upon the ramp and building it up in layers. Ramp

grade should not be so steep as to strain the truck or to

prevent them from dumping cleanly.

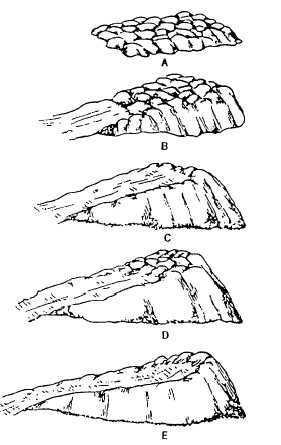

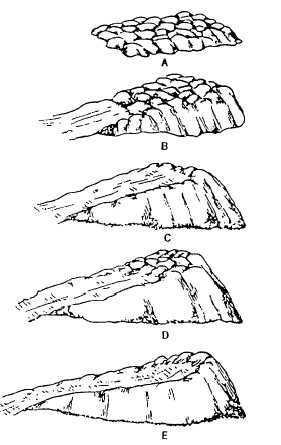

Figure 6-14 illustrates the building of a stockpile by

use of a spiral ramp. This is started as a narrow, backup

pile that is spread on the outside far enough to protect

the ramp from caving in and well past the center on the

inside. The ramp, steadily rising, is turned and comes

back on the far side, parallel with the first section, but

above it. Material is still dumped far enough to the

outside and inside to protect the ramp.

When material is too soft or too loose to support

trucks, the ramps may be strengthened by the use of wire

mats, or small quantities of screening, soil, or other

binders if their use will not spoil the value of the

stockpile.

Figure 6-13.-Ramp stockpile.

Figure 6-14.-Spiral ramp stockpile.

Trucks may be kept off a stockpile, either for safety

measures or to avoid packing, by dumping on level

ground and piling by dozer or loader. The loader is more

efficient because it can combine lift with push for

higher, steeper piles with shorter moves and less power

consumption heaping stockpiles rapidly. The dozer is

entirely flexible in placing or varying the size and shape

of a stockpile and can be used for a variety of other work;

however, it must move its entire weight up the pile with

each load, and the constantly working tracks on the

dozer may be subjected to severe wear in sand or other

abrasive materials. Also, the tracks may pack or crush

soft materials that drastically reduces their value.

Choice of tracks or wheels depends on the

availability of equipment and the type of material.

Wheels provide more compaction and cause less

breakage into fines. They wear less in sand or gravel as

long as the operators avoid spinning the tires during

loading operations; however, wheels become

ineffective under slippery conditions.

Loaders of either type can be used to reclaim the

pile, loading the material into trucks or carrying it to

hoppers or to the area of use. Tires have an advantage

in both speed and economy for carries greater than 50

feet.

6-14