screen out fines. This enables you to direct certain

selected material to receive special or additional

processing. Certain material may also be directed to

bypass processing that is not required.

Screens consist of two, three, or four layers or decks

of open-mesh screen wire cloth, mounted one above the

other in a rectangular metal box. The screen surfaces are

vibrated to aid sorting. Material is fed at one end and is

separated into size ranges as it passes over the screening

surface. The screening process is based upon the fact

that particle sizes smaller than the screen cloth opening

size passes through the screen and oversized particles

are retained.

Stratification of the feed material must occur

rapidly as the material is passed over the screen surface

to obtain good efficiency and high capacity. This ensures

the smaller particles can move quickly to the bottom and

fall through the screen openings, and the larger

oversized particles are carried to the top of the feed

stream where they are retained and directed off the end

of the screen. The desired performance of specific

screens is obtained by varying the degree of inclination,

frequency and amplitude of stroke, and the direction of

throw. Screens may be horizontal or inclined up to about

20 degrees and vibrate at 850 to 1,250 strokes per

minute, depending upon the particular application.

CAPACITY.– Capacity is the rate in tons per hour

at which a screen produces (passes) the material desired.

The capacity of a screen is the rate at which it separates

desired material from the feed.

FEEDING MATERIALS TO SCREEN.– Care

must be taken to spread the flow of material evenly

across the full width of the screen. The thickness of the

bed of feed material should be approximately four times

the screen opening size. If this is exceeded, the screen

becomes overloaded and the vibrations are dampened.

This results in the finer particles being unable to find

their way to the screen wire opening. When an

insufficient amount of material is fed, the total capacity

of the screen is not used.

VARIABLE FACTORS.– Numerous factors can

affect the performance of screens. Some examples of

these are as follows: shapes, weight, and gradation of

particles; degree of inclination and vibration; type of

wire screen cloth; position of the screen within the deck;

and wet screening (washing).

Screen Selection

Once the gradation of material has been determined,

screens must be selected that can segregate the materials

into appropriate sizes. The number of screens to be

selected is dependent upon the number of size ranges

into which the material must be segregated and the type

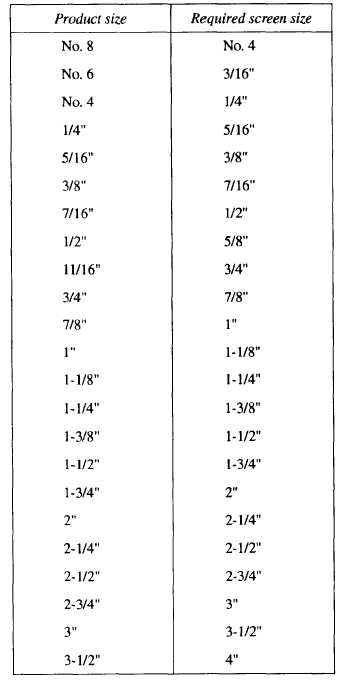

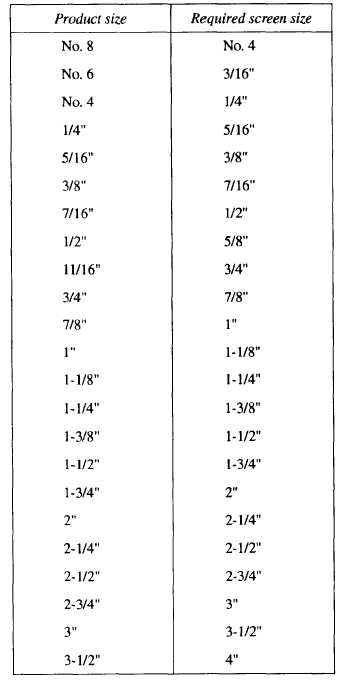

of equipment available for screening. Table 6-1 gives

the screen sizes of vibrating screens used to produce

specific sizes of aggregate.

Table 61.-Vibrating Screen Selection Chart

6-9