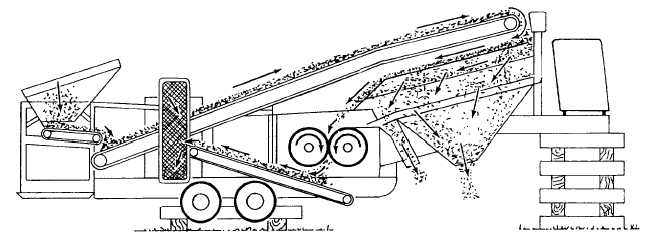

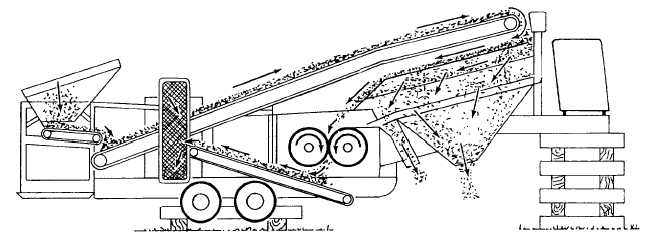

Figure 6-4.-Secondary unit.

Secondary Unit

The secondary unit (fig. 6-4) consists of a

reciprocating feed hopper, an overcrusher conveyer, a

two-deck vibrating screen, a dual roll crusher (fig. 6-5)

or hydrocone crusher (fig. 6-6), an undercrusher return

conveyer, a revolving elevator wheel, a diesel power

unit, and the running gear. The dual roll or hydrocone

crusher can be driven by a diesel engine or an electric

motor. All other components are driven by individual

electric motors and power is normally supplied by a

200-kW generator.

Material to be processed is introduced into the

hopper of the reciprocating feeder. The rate of flow is

controlled by the adjustable gate opening. Material is

deposited onto the overcrusher conveyer and carried to

the feed end of the top screen. Material that has been

crushed down to product size by the jaw crusher passes

the top screen. Oversized material is retained on the top

screen and directed through a dual roll crusher or

hydroccme crusher for further reduction.

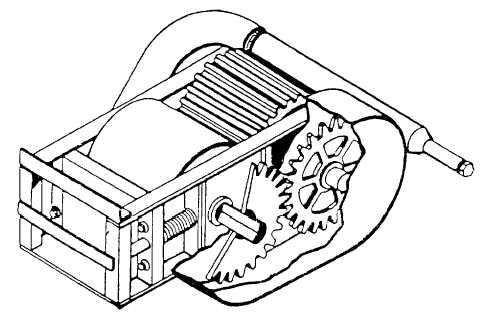

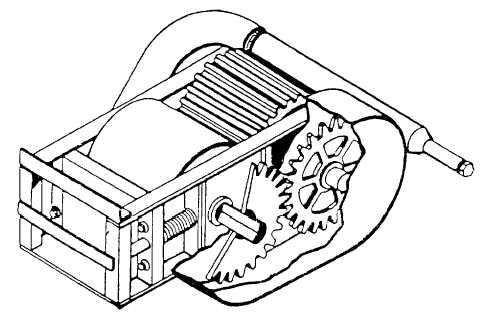

The dual roll crusher consists of a set of rolls that

revolve toward each other at a constant rim speed. Stone

particles are reduced in size as they are drawn between

the two rolls. Product setting is determined by the

Figure 6-5.-Dual roll crusher.

6-4