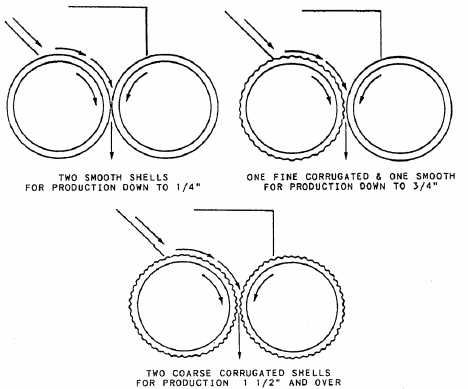

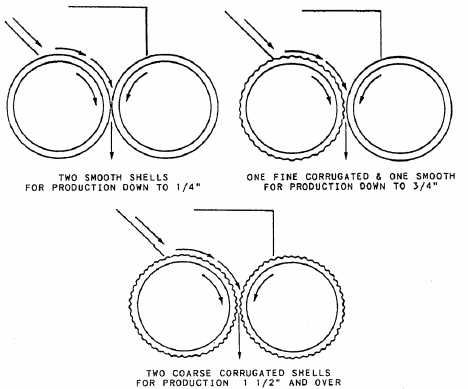

spacing between the rolls. It is necessary

to

set

the

opening

between

the

rolls

slightly closer than the top product size

required.

With

two

coarse

corrugated

shells

(fig.

6-7),

the

tip-to-tip

setting

produces a product larger than two smooth

shells set at the same distance.

In the NCF, the hydrocone crusher is

normally used as the secondary unit. These

machines have a conical or domed crushing

member called a cone, head, or sphere,

which moves in a small circle around a

vertical

axis

inside

a

fixed

bowl

or

mantle.

The

cone

may

be

relatively

stationary at the top and move at the

bottom only, or be mounted so that the

head can wobble as well as gyrate. The

crushing head is free to turn under the

thrust from the material being crushed.

The fineness of the product is adjusted by

raising or lowering the mantle.

Effective

feed

and

discharge

arrangements

are

essential

to

the

operation of any cone type of crusher. For

maximum crushing efficiency, feed must be

supplied to the crushing chamber in the

optimum

amount

and

distributed

evenly

around the entire crushing area.

NOTE:

Material

received

by

the

hydrocone crusher must be evenly distributed

nonsegregated feed. This means that the

material

entering

the

crusher

is

evenly

distributed

around

the

entire

crushing

chamber, with fine and coarse material

well

intermixed

in

the

feed.

Unevenly

distributed

or

segregated

feed

results

in

poor

manganese

wear,

reduced

capacity,

and

high

stresses

within

the

crusher. These problems can cause short

bearing

life

and

possible

failure

of

major components. An evenly distributed,

nonsegregated

feed

results

in

maximum

capacity,

a

uniform

product,

and

a

smooth running machine.

A pressure gauge is standard on all

hydrocone crushers. Erratic hydroset control

pressure and motor amperage (horse-power

draw)

readings

are

evidence

of

poor

feeding

conditions

and

uneven

feed

distribution in the crushing chamber. The

pressure

gauge

enables

the

operator

to

read high, average, and low pressures in

the hydroset control and take corrective

measures against erratic and high-pressure

conditions. The pressure gauge should be

checked

regularly

when

the

crusher

is

receiving the full or maximum amount of

feed.

NOTE: When excessive fluctuations occur

in the pressure in the hydroset control and

horsepower drew, determine and eliminate the

cause immediately. Operating the crusher

under

these

conditions

can

cause

Figure 6-7.—Shell combinations for dual roll crushers.

6-6