excessive shock loading and may result in serious

damage to the crusher.

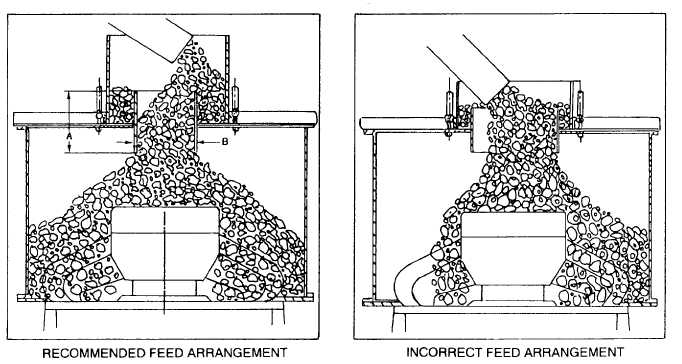

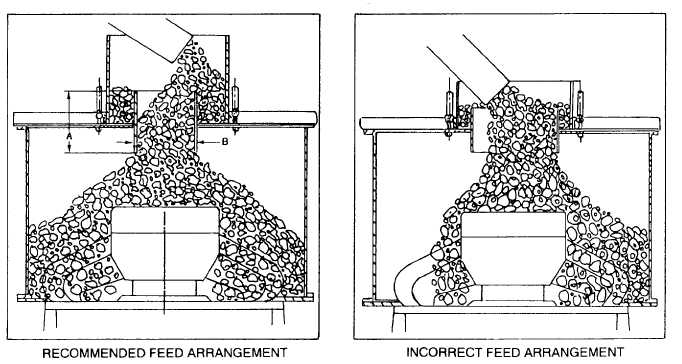

All hydrocone crushers are supplied with a feed

hopper with an adjustable feed spout that is adjustable

both vertically and horizontally. Horizontal adjustment

of the spout is accomplished by moving the adjustable

feed spout frame on the feed hopper. Slotted holes in the

upper flange of the feed hopper, and in the feed spout

frame, allow the feed spout to be moved horizontally in

order to position it properly over the feeder plate or

spider cap. The feed spout can be positioned vertically

by using studs and adjusting nuts to fasten the spout to

the frame. The vertical position of the spout controls the

amount of feed going into the hydrocone crusher.

Adjustable feed spout frame construction allows the

mounting of a suitable feedbox. Normally, it is better to

have the incoming feed hit the side of the feedbox, after

which it falls vertically through the feed spout. This is

the most effective way of obtaining proper feed to the

hydrocone crusher (fig. 6-8).

The discharge arrangement setup must allow the

material to discharge freely without backing up

underneath the crusher. Material backing up below and

into the hydrocone crusher can result in serious damage

to the machine.

A straight-down discharge is commonly used with

hydrocone crushers. With this arrangement, crushed

material falls into a stone box below the crusher.

Material passes through a hole in the stone box floor

onto a conveyer belt that carries it away. This discharge

arrangement helps prevent buildup of sticky materials

beneath the crusher.

The crushing chamber is annular (ring shaped).

Rock fed into the top falls between the cone and

the mantle and is crushed as the opening narrows with

the movement of the cone. When the opening widens

again, the pieces fall farther, to be crushed again

as the cone gyrates. The crushing action is similar to

that of a jaw crusher, except the squeeze comes from the

side rather than from the bottom and the curve of the

jaws.

The cone speed and the distance of travel must

be carefully synchronized. A wide space allows

pieces to fall more freely than a narrow one when the

cone is moving slowly; however, it allows pieces to fall

too far before the next impact. On the other hand, where

the space is narrow and the cone is moving rapidly,

the pieces cannot fall far enough and this causes

production to be low for the amount of power being

used.

CAUTION

DO NOT operate the cone crusher at a

smaller setting than that for which it was

designed. Operation at too small a discharge

Figure 6-8.-Recommended cone crusher feed arrangement.

6-7