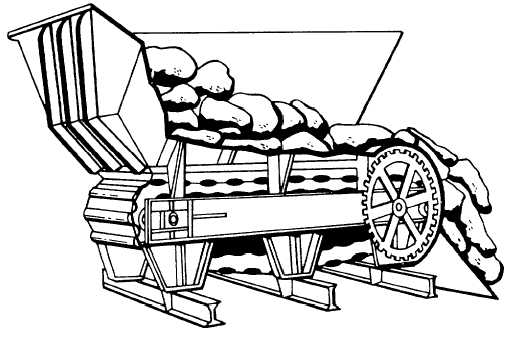

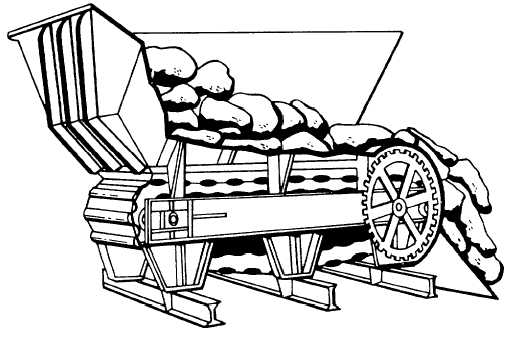

Figure 6-3.-Apron feeder.

4. The gradation of raw material.

5. The extent of wear to the corrugated surfaces of

the jaw plates.

6. The rate of feeding.

Feeding problems may develop due to irregular

shapes and unwieldy nature of quarry run rock. Feeding

problems can drastically reduce production. Some

common problems are blocking, bridging, choking, and

packing.

Blocking occurs when an oversize rock settles over

the jaw opening and stops the flow of incoming material.

The jaw continues to operate but no crushing takes

place. To prevent blocking, you should let the maximum

size of material processed be 2 inches less than the jaw

crusher size. Blocking can be controlled or eliminated

by using a scalping grizzly to prescreen material. For

optimum production, the ideal feed size is 75 percent of

the jaw size.

Bridging occurs when two rocks, within the

maximum size, arrive at the same time. The two rocks

interlock and bridge the jaws open. When this occurs,

all production stops. When large rocks approach the

opening, they should be fed individually to prevent

bridging.

Choking

continually

occurs when the jaw chamber is

overfilled. This creates an overload

condition and causes the engine to lug down and may

damage the equipment. For optimum production, the

operator should try to keep the jaw chamber 75 percent

full.

Packing occurs when feed material cakes and packs

in the crusher chamber. Plastic material, such as clay,

may become sticky and cause this problem. Packing can

become so severe that it completely stops production.

Packing can be reduced or eliminated by prescreening

or prewashing the material. In most cases, the most

practical solution is to wet down the material

thoroughly. Then process the material even though it is

almost in the form of a slurry.

The jaw crusher can produce at a rate of 55 to 185

tph, depending upon the product setting and the

toughness of the material being crushed. The maximum

product setting is 5 inches, and the minimum setting is

1 1/2 inches.

WARNING

Keep all parts of your body out of the jaw

cavity when you are operating or adjusting the

jaws.

6-3