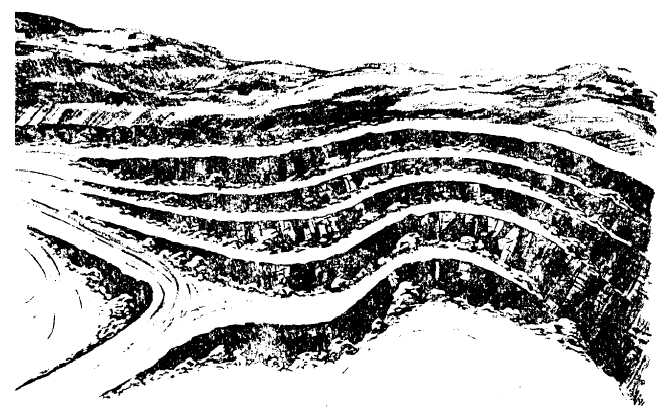

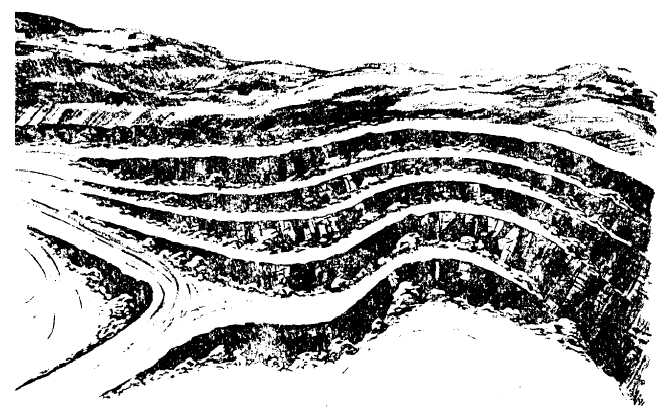

Figure 5-14.-Multiple-bench quarry.

than one level. All benches must be made wide enough

to allow the use of equipment to remove blasted rock

(50 feet minimum). Multiple-bench quarries make

possible greater continuity of operation than

single-bench quarries.

NOTE: When you are developing a multibench

quarry, blasting must be confined to only one bench at

a time. Simultaneous blasting at several levels is NOT

permitted under any circumstances.

QUARRY EQUIPMENT

CESE is available in the Naval Construction Force

TOA to enable construction units to meet their own

aggregate production requirements. Quarry equipment

is subject to exceptionally hard wear due to the abrasive

action of rock and rock dust; therefore, the operator’s

maintenance procedures contained in the

manufacturer’s maintenance and service manuals must

be strictly followed.

The equipment used in hard-rock quarries

consists of bulldozers, air compressors, rock drills,

drill steel and bits, loading and hauling equipment,

and miscellaneous tools. As the supervisor in charge

of quarry operations, you must ensure that operator’s

maintenance is performed and that all cutting edges,

end bits, teeth and shanks, dozer tracks, tires, blades,

and so forth, are checked daily for wear, adjustments,

and cracks.

Wearfacing

Equipment used in quarry operations should be

wear-faced. Wearfacing greatly extends the usable life

of construction equipment, ensures efficient operation

with less downtime, and greatly reduces the need for

spare parts. Guidelines for wearfacing equipment parts

and accessories are outlined in the NCF Welding

Materials Handbook, NAVFAC P-433.

5-15