setting may result in packing in the crusher

chamber, high loads and stresses, and possible

damage to major components.

After passing the dual roll crusher, the material is

recirculated to the top screen by means of a return

conveyer and a revolving elevator wheel. The material

from the hydrocone crusher is recirculated to the top

screen by means of a return conveyer and a crossover

chute. Any material still too large to pass the top screen

is routed through the roll crusher or hydrocone crusher

again. This is known as a “closed circuit” crushing

system. It is obvious that the product setting on the roll

crusher or hydrocone crusher should be set at or slightly

less than the opening size of the top screen.

The material retained on the bottom screen is the

product that is routed through a chute to a conveyer and

then delivered to the product stockpile. Material too

small to meet product specifications is screened out by

the bottom screen and delivered to a by-product

stockpile.

The secondary unit includes a bar type of scalping

screen that can be inserted into the top rim of the sloping

hopper. When inserted, this screen causes any oversized

material to be scalped and rolled off of the screen and

to the rear of the machine.

The same factors discussed for the jaw crusher also

affect the production of the roll crusher. By comparison,

dual roll crushers have a limited “stage of reduction”

capability. “Stage of reduction” is the difference,

expressed in inches or centimeters, between the

maximum input and maximum output size of material

due to a single crushing action. A stage of reduction of

3 inches (7.6 cm) indicates a 3-inch (7.6-cm) reduction

in maximum particle size. This reduction capability is a

function of the diameter of the rolls and of the nature of

the roll shell surface; therefore, every different size and

combination of roll shells has a somewhat different

stage of reduction capacity. For this reason the

maximum size of material to be fed to a dual roll crusher

is critical.

The maximum allowable feed size is the sum of the

stage of reduction capability and the product setting. If

the maximum feed size is exceeded, unsatisfactory

results likely to occur are as follows:

1. Retarded production

2. Excessive roll shell wear

3. Excessive long-and-flat particles

These units also have a wide range of production

capability. The actual rate of production in tons per hour

is usually determined by the screening capacity of the

screens. In some cases, the rate may be limited by the

capacity of the dual roll crusher or hydrocone crusher.

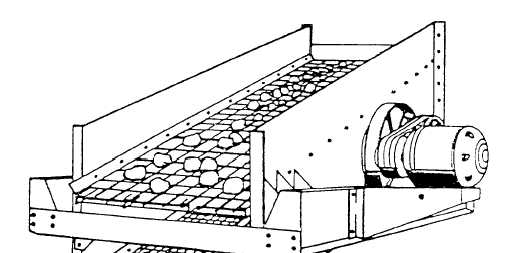

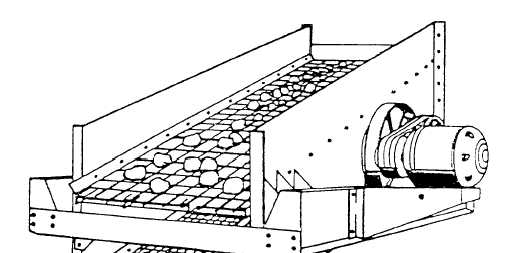

Screens

Crushed rock particles are separated into two or

more particle size ranges by the use of screens (fig. 6-9).

Screens are also used to scalp off oversized rock and to

Figure 6-9.-Vibrating screen box.

6-8