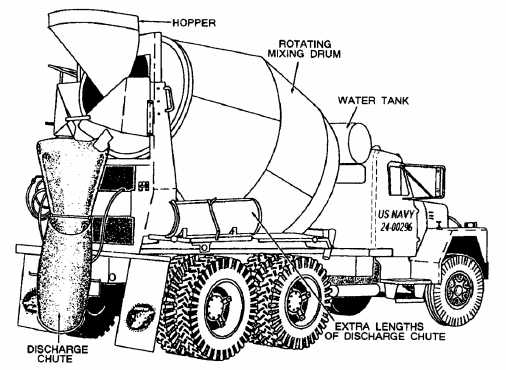

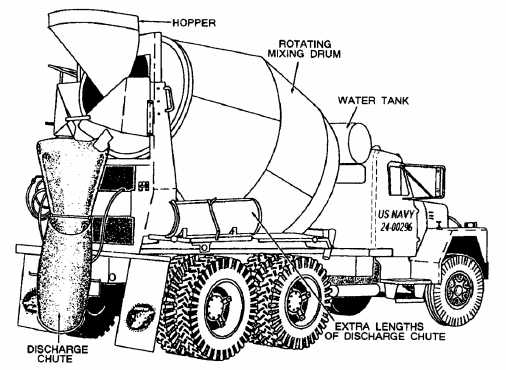

Figure 7-1.-Transit mixer.

equipment.

If

the

concrete

cannot

be

discharged

immediately,

the

operator

should turn the drum at the minimum

agitating

speed

of

2

revolutions

per

minute. When the transit mixer arrives at

the project having used the minimum amount

of mixing turns, the operator is able, if

necessary,

to

delay

discharging

the

concrete. Delay is limited by the maximum

of 300 rotations allowed.

Remixing Concrete

Concrete begins to stiffen as soon

as

the

cement

and

water

are

mixed.

However,

the

degree

of

stiffening

that

occurs in the first 30 minutes is not

usually a problem; concrete that is kept

agitated generally can be placed within 1

1/2 hours after mixing.

Fresh

concrete

left

to

agitate

in

the mixer drum may be used if upon

remixing

it

becomes

sufficiently

plastic

to be consolidated in the forms. Under

careful supervision a small amount of water

may

be

added

to

remix

the

concrete

provided the following conditions are met:

(1) maximum allowable water-cement ratio

is not exceeded, (2) maximum allowable

slump

is

not

exceeded,

(3)

maximum

allowable mixing and agitating time (or

drum revolutions) are not exceeded, and

(4) concrete is remixed for at least half

the minimum required mixing time or number

of

revolutions.

Adding too much water to make

concrete more fluid should not be allowed

because this lowers the quality of the

concrete. Remixed concrete can be expected

to harden quickly. Subsequently, a cold

joint may develop when concrete is placed

next to or above the remixed concrete.

Mixer Cleaning

After

the

load

of

concrete

is

discharged from the mixer, the operator

should wash off all excess concrete in the

mixer drum and blades, the discharge chute

opening, and the discharge chute before it

has a chance to harden. Spraying 15 to 25

gallons of water into the drum while it is

rotating will clean the inside of the drum

as well as remove all grout which may have

collected

in

the

water

nozzle

during

discharge. A washdown hose is provided on

the mixer to clean areas accessible from

the outside. A clean mixer produces a more

satisfactory

mixing

and

discharge

of

concrete.

At the plant, flush a minimum of

150 to 250 gallons of water, depending

on the size of the mixer, into the drum.

With the flush water in the drum, rotate

the drum in the mixing direction for a

few

minutes,

then

discharge

the

flush

water at the maximum drum rpm. Complete

the

cleaning

of

the

outside

of

the

mixer,

particularly

around

the

discharge

end.

7-5