CHAPTER 8

ASPHALT PLANT SUPERVISOR

The

Naval

Construction

Force

(NCF)

uses

various

makes

and

models

of

asphalt

plants

in

both

the

Atlantic

and

Pacific

Fleet

deployment

sites.

As

an

asphalt

plant

supervisor,

you

are

a

key

member

and

share

the

responsibility

for

producing

a

quality

mix.

You

must

be

aware

of

all

operational

functions

of

the

plant

and

bring

to

the

attention

of

the

Alfa

company

operations

chief

any

detected

problems

or

potential

problems.

Additionally, you must be aware of all

federal,

state,

and

local

regulations

and

ordinances

relating

to

the

operation

of

the

plant,

such

as

air

and

water

pollution

restrictions,

anti

noise

requirements,

restricted

hours

of

operation,

and

so

forth.

Before

d e p l o y i n g ,

c o n t a c t

t h e

COMSECOND/COMTHIRDNCB

equipment

offices for Environmental Protection Agency

(EPA)

directives,and

operator’s

manuals

that

relate

to

the

asphalt

plant

at

your

prospective

deployment

site.

ASPHALT PLANT SUPERVISOR

RESPONSIBILITIES

This

chapter

presents

the

basic

information

concerning

the

operations

of

asphalt plants and the production and uses

of bituminous materials. The Seabees need

well-qualified

personnel

to

operate

and

maintain

asphalt

plants.

To

ensure

personnel

are

qualified,

you

must

emphasize

on-the-job

training

programs.

Also,

personnel

must

gain

a

thorough

understanding

of

the

manufacturers’

operator and maintenance manuals.

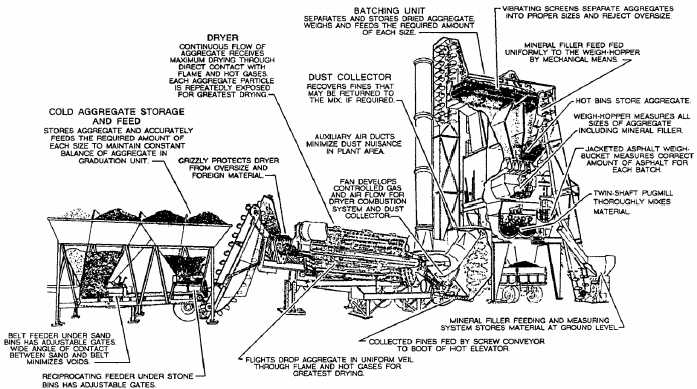

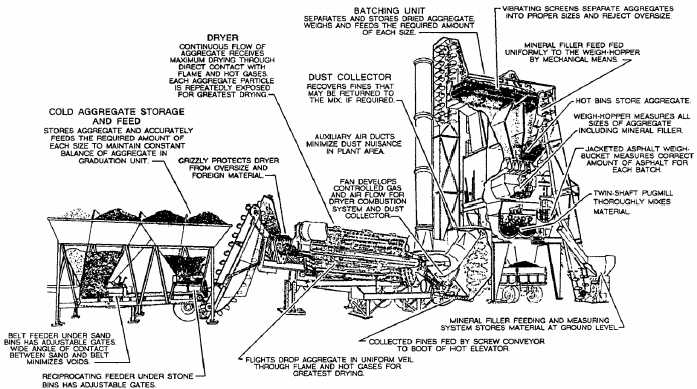

An asphalt plant is an assembly of

mechanical,

computerized,

electronic

equipment where aggregates are blended,

heated, dried, and mixed with asphalt to

produce

a

hot-asphalt

mix

that

meets

specified

requirements.

An

asphalt

plant

can

be

small,

large,

stationary,

or

portable.

Whatever

the

size

or

configuration,

every

plant

can

be

categorized

as

either

a

batch

asphalt

plant

(fig.

8-1),

a

continuous-flow

Figure 8-1.—Batch asphalt plant.

8-1