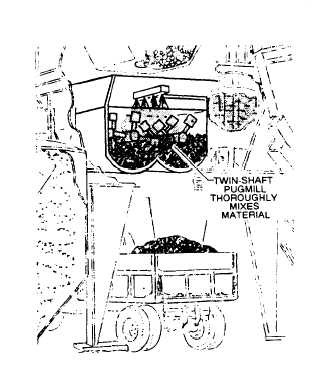

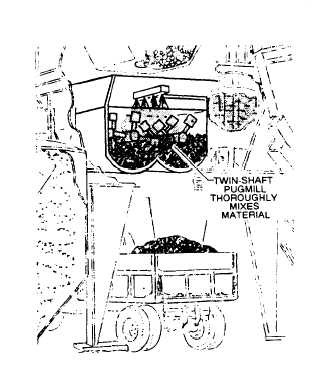

Figure 8-4.-Pugmill

plant. The feeder may be charged by a clamshell or

front-end loader. Aggregate feeder units should have

controls that can beset and secured to produce a uniform

flow of aggregate to the cold elevator.

For a uniform OUTPUT from the asphalt plant,

INPUT must be accurately measured. The importance

of feeding the exact amounts of each size aggregate into

the dryer at the correct rate of flow cannot be

overemphasized.

The following conditions ensure a uniform flow of

aggregate sizes:

l Correct sizes of aggregate in stockpiles.

l No intermixing of stockpiles.

. Accurately calibrated, set, and secured feeder

gates.

. Gates kept free of obstruction.

l No excessive arching in the fine aggregates.

Arching can be minimized by using rectangular (rather

than square) openings above the feeders or placing

Figure 8-5.-Aggregate storage and cold-feed system.

8-3