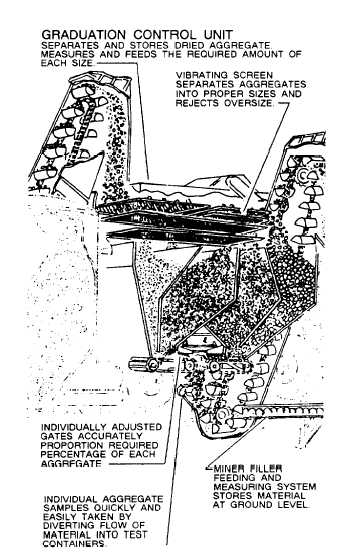

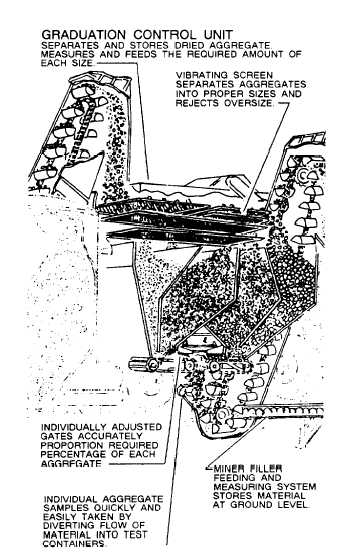

Figure 8-9.-Gradation control unit.

transferred to a storage silo. This material is often used

in the hot mix.

When the material removed from the dust collector

can be recombined satisfactorily with the aggregates in

the mix, some or all of it may be returned to the plant.

The amount returned depends upon the combined

grading of the finished mix. When the collected dust is

unsatisfactory or is prohibited by the mix specifications,

it is removed from the bottom of the collector and

wasted.

Hot Screens

After the aggregates have been heated and dried,

they are carried by a hot elevator to the gradation unit,

In the gradation unit, the hot aggregate passes over a

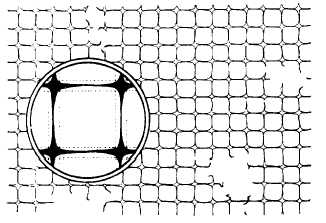

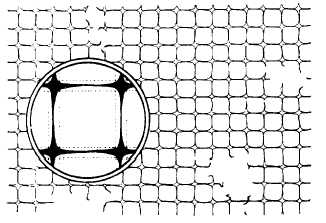

Figure 8-10.-Screen wear.

series of screens. The function of the screens is to

separate the hot aggregate into the specified sizes

accurately and deposit those sizes in hot bins.

The gradation control unit (fig. 8-9) or screening

unit includes a set of several different-sized vibrating

screens. The top screen is a scalping screen that rejects

and carries off oversized aggregates. This is followed by

one or two intermediate-sized screens, decreasing in

size from the top to bottom. The very bottom screen is

normally a sand screen. The effective screening area

must be large enough to handle the maximum amount

of feed delivered to separate the hot aggregates properly;

therefore, the capacity of the screens should be checked

against the capacity of the dryer and the capacity of the

pugmill.

When too much material is fed to the screens or the

screen openings are plugged, many particles that should

pass through ride over the screen and drop into a bin

designated for larger sized aggregate. When screens are

worn (fig. 8-10) or torn, resulting in enlarged openings

and holes, oversized material will go into bins intended

for smaller sized aggregate. Fine aggregate misdirected

into bins intended for larger aggregate is know as

“carry-over.”

Carry-over can cause a lack of uniformity in the

aggregate gradation and in the mixture. Additionally,

excessive carry-over adds to the amount of fine

aggregate in the total mix, thus increasing the surface

area to be coated with asphalt. Excessive carry-over, or

its fluctuations, can be detected by a sieve analyses made

from the contents of the individual hot bins and must be

corrected immediately. Corrective measures include the

cleaning of screens, the regulation of the quantity of

material coming from the cold feed, or a combination of

both. Some carry-over is permitted in normal screening;

8-8