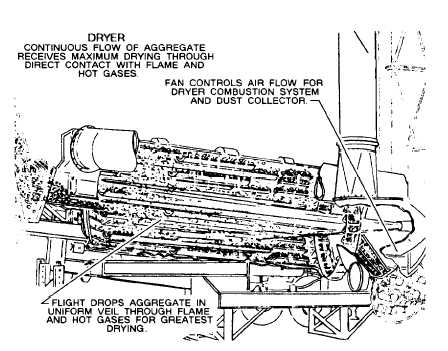

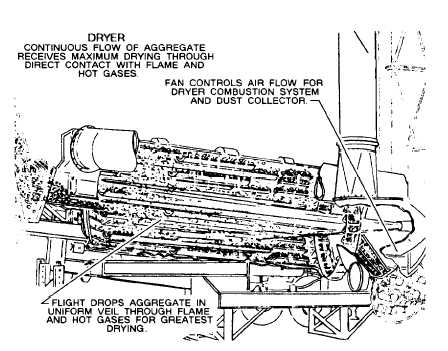

Figure 8-7.-Dryer.

when calibrating gates through which fine aggregates

are flowing.

For uniform flow, gates that feed coarse aggregate

should not be set at a height less than 2 1/2 to 3 times

the largest aggregate size; for example, if a gate is

feeding aggregate that has a maximum size of 1 inch,

the gate should not be set at less than 2 1/2 or 3 inches.

Sometimes it may be necessary to restrict the opening

width to provide the necessary opening height.

Before you set the cold-feed gates, the production

volume of the plant in normal operation must be

determined. this can be estimated from the plant size

(dryer, screening, and mixing capacities) and mixing

cycle time. Then, using the gate calibration charts, each

gate is set to deliver its share of the desired volume of

aggregate.

Grading of the individual cold aggregate is

determined by sieve analysis. The percentage of each

size of aggregate to be used is calculated by trial and

error.

The proportions required on the basis of these

percentages will determine the gate settings. These

settings should be checked by the same method used in

calibrating the gate originally.

The setting should be considered tentative because

the cold aggregate may vary in grading and moisture

with the weather and other conditions that will affect its

bulking and flow.

The hot bins should be watched carefully and the

cold aggregate feeders regulated to see that they do not

run out of material or overflow.

Dryer

From the aggregate cold-feed system, aggregates

are delivered to the dryer. The dryer (fig. 8-7) is a

revolving cylinder in which the aggregate is dried and

heated by an oil or gas burner. The cylinders used range

from 3 to 10 feet in diameter and from 15 to 40 feet in

length. A cylinder is usually equipped with longitudinal

cups or channels (called lifting flights) that lift the

aggregate and drop it in veils through the burner flame

and hot gases. The slope of the cylinder, its speed,

diameter, length, and the arrangement and number of

flights control the length of time required for the

aggregate to pass through the dryer.

The dryer performs two functions: (1) it removes

moisture from the aggregate and (2) it heats the

aggregate to mixing temperature.

The dryer includes an oil or gas burner with a blower

fan to provide the primary air for combustion of the fuel

and an exhaust fan to create a draft through the dryer.

For efficient dryer operation, the air that is combined

with the fuel for combustion must be in balance with the

8-5