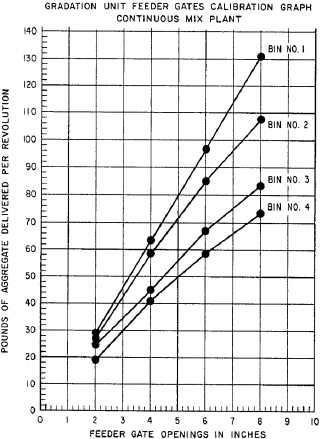

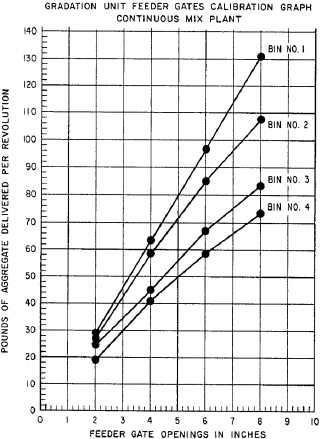

Figure 8-6.-Calibration chart, gradation

feeder gates.

vibrators

on

the

outside

of

the

fine

aggregate bins, or both. Vibrators should

be wired to cut off automatically when the

feeder

stops.

This

eliminates

excessive

packing in the bin.

The

following

conditions

underscore

the need for proper cold feeding:

Wide variations in the moisture

content or in the quantity of a specific

aggregate at the cold feed may cause a

considerable change in the temperature of

the aggregate leaving the dryer.

A sudden increase in the cold

feed can overload the screens, creating a

carry-over of the fine aggregate into the

coarse aggregate hot bins.

Erratic feeding may cause some

bins

to

overfill

while

starving

others.

This can result in the following problems:

1. Layers of variable grading in the

hot bin gradation unit storage,

especially

in

the

fine

bin,

resulting in alternating rich and

lean batches

2. An overloaded dust collection system

3. A reduced dryer draft

The

cold

aggregate

feeder

gates

should

be

calibrated.

Most

manufacturers

furnish

approximate

calibrations

for

the

gate openings of their equipment. When

these are available, they are helpful in

making the initial gate setting. But the

only accurate way to set gates is by

making a calibration chart for each gate,

using the aggregate to be used in the mix.

The

gate

opening

(in

inches

or

square inches) is plotted on the chart as

the horizontal coordinate, and the pounds

of material per revolution of the feeding

mechanism (or pounds per minute) is the

vertical

coordinate.

When

the

calibration

chart is being prepared, the gate is set,

usually at 25 percent or less of the total

opening, and the feeder is started. When

the

feeder

is

running

normally,

the

material is measured into a tare container

and weighed at known time intervals (or

number

of

revolutions).

This

gives

one

point

on

the

calibration

chart.

The

operation is repeated for three or more

gate openings and the points connected on

the chart (fig. 8-6). After the gates have

been

calibrated

and

locked,

minor

adjustments may be necessary to assure

uniform

production.

When the gates discharge on to the

belt conveyer, their output may be checked

by closing all of the gates except one,

which is set at one of the calibration

points. When the gates cannot be closed

completely, it may be necessary to stop

the

feeder

or

disconnect

it

if

it

is

mechanically

driven.

The plant is started and brought to

normal operating speed. Then the plant is

stopped and the material from a measured

section

of

the

belt

is

removed

and

weighed, using care to remove all fines.

The weight of the material, divided

by

the

length

(in

feet)

of

the

belt

section, multiplied by the belt speed (in

feet per minute), will give the amount of

material delivered per minute from the

gate opening. The material from other gate

openings is determined in the same manner

and the gate calibration chart plotted as

described

above.

When variable speed drives are used to

control

belt

feeders,

calibration

is

simplified.

The

gate

opening

can

be

estimated, and the speed of the belt can be

increased

or

decreased

to

deliver

the

required percentage and tonnage of aggregate.

In calculating the output of a gate

for a given opening, deduct the weight of

the

surface

moisture

on

the

aggregate

being

weighed.

This

is

very

important

8-4