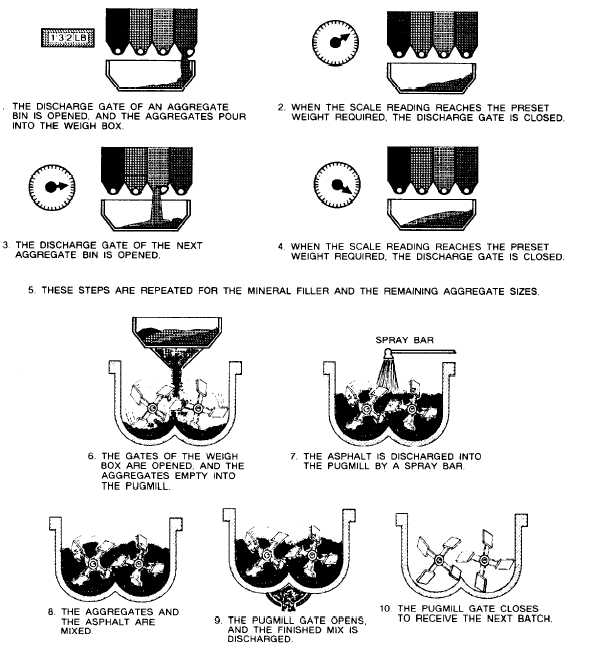

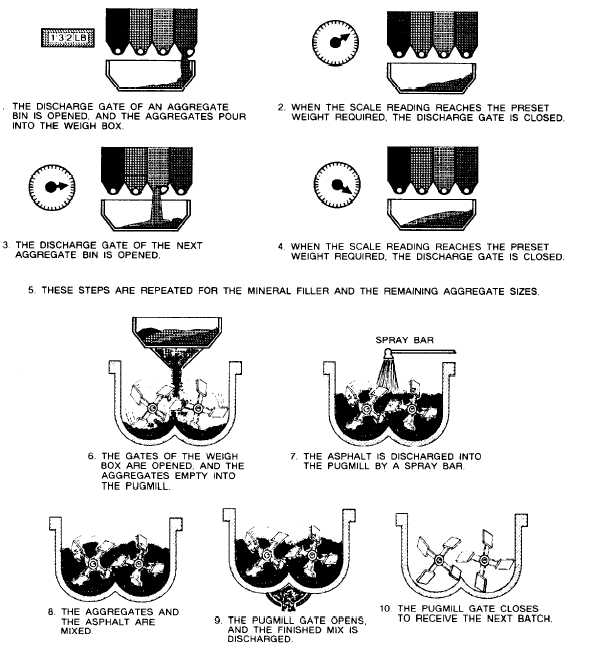

Figure 8-14.-Typical batch plant cumulative scale settings and cycle.

is screened into different sizes and stored by size in

separate bins.

From the hot bins the aggregates are deposited into

a weigh-hopper. Coarse aggregates are usually the first

to be deposited into the weigh-hopper, the

intermediate-size aggregates next, and the fine

aggregates last. This sequence is designed to place the

fines of the aggregates at the top of the aggregates

deposited in the weigh-hopper where they cannot leak

out through the gate at the bottom of the weigh-hopper,

This system also allows the most efficient utilization of

the available volume in the weigh-hopper. The

weigh-hopper is suspended from scale beams and the

scales indicate the weight of the full amount of

aggregate entering the hopper.

When each size of aggregate is deposited into the

weigh-hopper, the weights to be drawn from the hot bins

are marked on the scale dial. Because the scales indicate

the weights cumulatively, the dial must be marked

accordingly. Figure 8-14 shows how the cumulative

scale settings are used to control the proportion of

aggregates drawn from each bin.

8-13