Asphalt Introduction

From the weigh-hopper, the aggregates are

deposited into the plant pugmill (mixing chamber) and

are blended with the proper proportion of asphalt. In a

typical plant system, asphalt is weighed separately in a

weigh bucket before being introduced into the pugmill.

When the asphalt reaches a predetermined level in the

weigh bucket, a valve in the delivery line closes to

prevent excess asphalt from being discharged into the

bucket. The asphalt is then pumped through spray bars

into the pugmill. Asphalt buckets should be checked for

accuracy in the mornings. New asphalt loosens some of

the old asphalt that accumulated the previous day on the

sides and bottom of the bucket. Loss of this accumulated

asphalt changes the tare weight of the bucket.

Pugmill Mixing

Asphalt and aggregates are blended in a chamber

called the pugmill. The pugmill consists of a lined

mixing chamber with two horizontal shafts on which

several paddle shanks, each with two paddle tips, are

mounted. The paddle tips are adjustable and fairly easily

replaced.

The paddle areas are adjusted to ensure there are no

“dead areas” in the pugmill. A “dead area” is a location

where aggregates can accumulate out of reach of the

paddles and not be thoroughly mixed. Dead areas can

be avoided by making sure the clearance between the

paddle tips and the liner is less than one half of the

maximum aggregate size.

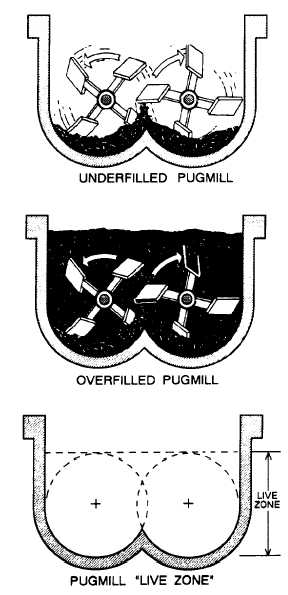

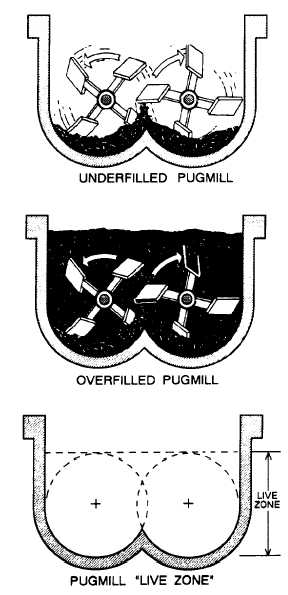

Nonuniform mixing can occur if the pugmill is

overfilled (fig. 8-15). When the plant is operating at full

production, the paddle tips should be barely visible at

the surface of the material during mixing. If the material

is too high, the surface aggregates will tend to “float”

above the paddles and will not thoroughly mix.

Conversely, in a pugmill containing too little aggregate

(fig. 8-15), the tips of the paddles rake through the

material without mixing it. These problems can be

avoided by following the manufacturer’s pugmill batch

rating recommendation. Normally, the rating is based on

a percentage of the capacity of the pugmills “live zone.”

This live zone (fig. 8-15) is the net volume in cubic feet

below a line extending across the top are of the inside

body shell radius with shafts, liners, paddles, and tips

deducted.

Figure 8-14 presents the mixing cycle during which

the aggregates, mineral filler, and asphalt are blended in

asphalt hot mix in the pugmill. The length of time

Figure 8-15.-Typical pugmill.

between the opening of the weigh box gate (Step 6 in

the figure) and the opening of the pugmill discharge

gate (Step 9) is referred to as the batch mixing time.

The batch mixing time must be long enough to

produce an homogeneous mixture of evenly distributed

and uniformly coated aggregate particles. If the

mixing time is too long, the lengthy exposure of the

thin asphalt film to the high-aggregate temperature in

the presence of air can affect the asphalt and reduce

the durability of the mix. The speed of the mixer shafts

and the arrangement and pitch of the paddles are

factors governing the efficiency of the mixing. Most

job specifications require the use of a timing device

to monitor batch mixing time.

8-14