If an inspection discloses any unsatisfactory

conditions in a line, see that the line is destroyed or cut

into small pieces as soon as possible. This precaution

prevents the defective line from being used for hoisting.

CHAIN

In the NCF, never use a chain when it is possible to

use wire rope. The reason for this is because, unlike wire

rope, chain does not have reserve strength and does not

give any warning that it is about to fail; therefore, you

will not be alerted of a potentially hazardous condition.

Chain is better suited than wire rope for some jobs

because it is more resistant to abrasion, corrosion, and

heat. When chain is used as a sling, it has no flexibility

and grips the load well.

CHAIN GRADES

It is difficult to determine the grade of some types

of chains by looking at them. Most chains used by the

NCF are class A chain. If you are uncertain of the class

or size of a chain, ask your supervisor.

CHAIN STRENGTH

Before lifting with a chain, make sure the chain is

free from twists and kinks. A twisted or kinked chain

placed under stress could fail even when handling a light

load. Additionally, ensure that the load is properly seated

in the hook (not on the point) and that the chain is free

from nicks or other damage. Avoid sudden jerks in

lifting and lowering the load, and always consider the

angle of lift with a sling chain bridle.

The strength of any chain will be affected when it

has been knotted, overloaded, or heated to temperatures

above 500°F.

HANDLING AND CARE OF CHAIN

When hoisting heavy metal objects using chain for

slings, you should insert padding around the sharp

corners of the load to protect the chain links from being

cut.

Store chains in a clean, dry place where they will

not be exposed to the weather. Before storage, apply a

light coat of lubricant to prevent rust.

Do NOT perform makeshift repairs, such as

fastening links of a chain together with bolts or wire.

When links become worn or damaged, cut them out of

the chain, then fasten the two nearby links together with

a connecting link. After the connecting link is closed,

welding makes it as strong as the other links. For cutting

small-sized chain links, use bolt cutters. To cut

large-sized links, use a hacksaw.

Inspect the chain to ensure it is maintained in a safe,

operating condition. A chain used continuously for

heavy loading should be inspected frequently. Chain is

less reliable than manila or wire rope slings because the

links may crystallize and snap without warning.

Examine the chain closely link by link and look for

stretch, wear, distortion, cracks, nicks, and gouges. Wear

will usually be at the ends of the links where joining

links rub together. If you find wear, lift each link and

measure its cross section.

NOTE: Remove chains from service when any link

shows wear more than 25 percent of the thickness of the

metal.

Replace any link that shows cracks, distortion,

nicks, or cuts; however, if a chain shows stretching or

distortion of more than 5 percent in a five-link section,

discard and destroy the entire chain.

Remove chains from service when links show any

signs of binding at the juncture points of the links. This

condition indicates collapse in the sides of the links has

occurred as a result of stretching.

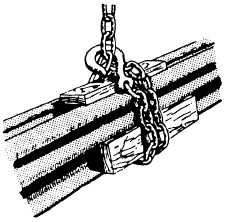

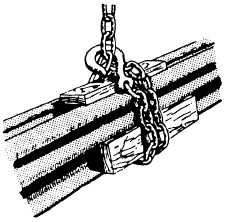

Before lifting with a chain, first place dunnage

between the chain and the load to provide a gripping

surface. For hoisting heavy metal objects with a chain,

always use chafing gear around the sharp corners on the

load to protect the chain links from being cut. As chafing

gear, use either planks or heavy fabric. In handling rails

or a number of lengths of pipe, make a round turn and

place the hook around the chain, as shown in

figure 13-29.

Figure 13-29.—Chain sling.

13-15