work right, its wires and strands must be free to move.

Friction from corrosion or lack of lubrication shortens

the service life of wire rope.

Deterioration from corrosion is more dangerous

than that from wear, because corrosion ruins the inside

wires—a process hard to detect by inspection. Deterio-

ration caused by wear can be detected by examining the

outside wires of the wire rope, because these wires

become flattened and reduced in diameter as the wire

rope wears.

NOTE: Replace wire rope that has wear of one third

of the original diameter of the outside individual wires.

Both internal and external lubrication protects a

wire rope against wear and corrosion. Internal

lubrication can be properly applied only when the wire

rope is being manufactured, and manufacturers

customarily coat every wire with a rust-inhibiting

lubricant, as it is laid into the strand. The core is also

lubricated in manufacturing.

Lubrication that is applied in the field is designed

not only to maintain surface lubrication but also to

prevent the loss of the internal lubrication provided by

the manufacturer. The Navy issues an asphaltic

petroleum oil that must be heated before using. This

lubricant is known as Lubricating Oil for Chain, Wire

Rope, and Exposed Gear and comes in two types:

l Type I, Regular: Does not prevent rust and is used

where rust prevention is not needed; for example,

elevator wires used inside are not exposed to the weather

but need lubrication.

l Type II, protective: A lubricant and an anti-

corrosive— it comes in three grades: grade A, for cold

weather (60°F and below); grade B, for warm weather

(between 60°F and 80°F); and grade C, for hot weather

(80°F and above).

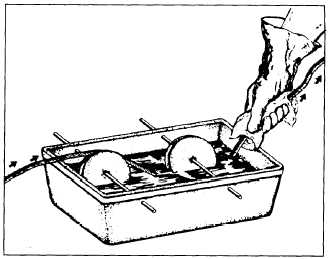

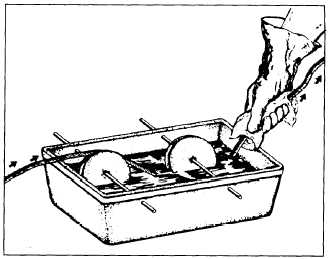

The oil, issued in 25-pound and 35-pound buckets

and in 100-pound drums, can be applied with a stiff

brush, or the wire rope can be drawn through a trough

of hot lubricant, as shown in figure 13-20. The

frequency of application depends upon service

conditions; as soon as the last coating has appreciably

deteriorated, it should be renewed.

CAUTION

Avoid prolonged skin contact with oils and

lubricants. Consult the Materials Safety Data

Sheet (MSDS) on each item before use for

precautions and hazards. See your supervisor

for copies of MSDSs.

Figure 13-20.—Trough method of lubricating wire rope.

A good lubricant to use when working in the field,

as recommended by COMSECOND/COMTHIRD-

NCBINST 11200.11, is a mixture of new motor oil and

diesel fuel at a ratio of 70-percent oil and 30-percent

diesel fuel. The NAVFAC P-404 contains added

information on additional lubricants that can be used.

Never lubricate wire rope that works a dragline or

other attachments that normally bring the wire rope in

contact with soils. The reason is that the lubricant will

pick up fine particles of material, and the resulting

abrasive action will be detrimental to both the wire rope

and sheave.

As a safety precaution, always wipe off any excess

oil when lubricating wire rope especially with hoisting

equipment. Too much lubricant can get into brakes or

clutches and cause them to fail. While in use, the motion

of machinery may sling excess oil around over crane

cabs and onto catwalks making them unsafe.

NOTE: Properly dispose of wiping rags and used

or excess lubricant as hazardous waste. See your

supervisor for details on local disposal requirements.

WIRE ROPE ATTACHMENTS

Many attachments can be fitted to the ends of wire

rope, so the rope can be connected to other wire ropes,

pad eyes, or equipment.

Wedge Socket

The attachment used most often to attach dead ends

of wire ropes to pad eyes or like fittings on cranes and

13-10