Kinking can be prevented by proper uncoiling and

unreeling methods and by the correct handling of the

rope throughout its installation.

Drum Winding

Spooling wire rope on a crane hoist drum causes a

slight rotating tendency of the rope due to the spiral lay

of the strands. Two types of hoist drums used for

spooling wire rope are as follows:

1. Grooved drum. When grooved drums are used,

the grooves generally give sufficient control to wind the

wire rope properly, whether it is right or left lay rope.

2, Smooth-faced drum. When smooth-faced drums

are used, where the only other influence on the wire rope

in winding on the first layer is the fleet angle, the slight

rotational tendency of the rope can be used as an

advantage in keeping the winding tight and uniform.

NOTE: Using the wrong type of wire rope lay

causes the rotational tendency of the rope to be a

disadvantage, because it results in loose and nonuniform

winding of the rope on the hoist drum.

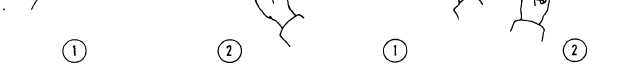

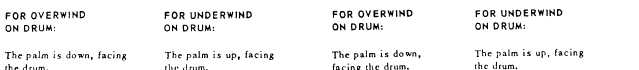

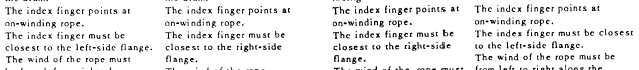

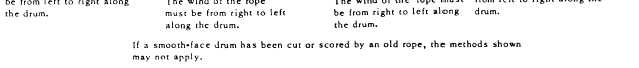

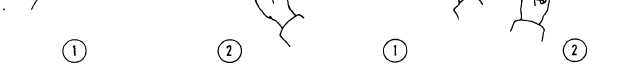

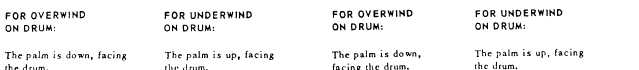

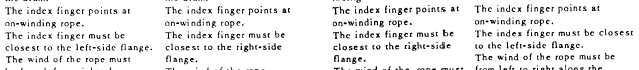

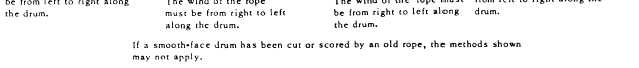

Figure 13-15 shows drum winding diagrams for

selection of the proper lay of rope. Standing behind the

hoist drum and looking toward an oncoming overwind

rope, the rotating tendency of right lay rope is toward

the left; whereas, the rotating tendency of a left lay rope

is toward the right.

Refer to figure 13-15. With overwind reeving and a

right lay rope on a smooth-faced drum, the wire rope

bitter end attachment to the drum flange should be at the

left flange. With underwind reeving and a right lay rope,

the wire rope bitter end attachment should beat the right

flange.

When wire rope is run off one reel onto another or

onto a winch or drum, it should be run from TOP TO

Figure 13-15.—Different lays of wire rope winding on hoist drums.

13-7