ordinarily used and should be spaced as far apart as

possible.

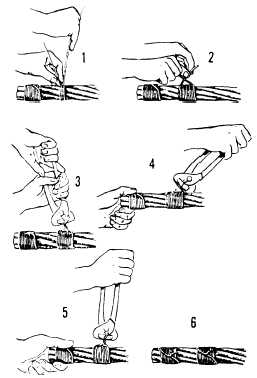

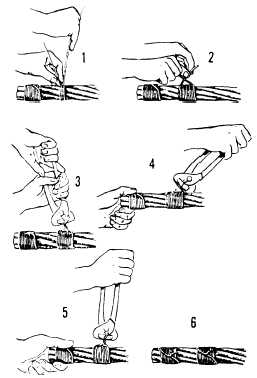

Seizing and Cutting

The makers of wire rope are careful to lay each wire

in the strand and each strand in the rope under uniform

tension. If the ends of the rope are not secured properly,

the original balance of tension will be disturbed and

maximum service cannot be obtained because some

strands can carry a greater portion of the load than

others. Before cutting steel wire rope, place seizing on

each side of the point where the rope is to be cut

(fig. 13-18).

A rule of thumb for determining the size, number,

and distance between seizing is as follows:

1. The number of seizing to be applied equals

approximately three times the diameter of the rope.

Example: 3 x 3/4-inch-diameter rope = 2 1/4 inches.

Round up to the next higher whole number and use three

seizing.

2. The width of each seizing should be 1 to 1 1/2

times as long as the diameter of the rope.

Example: 1 x 3/4-inch-diameter rope = 3/4 inch.

Use a 1-inch width of seizing.

Figure 13-18.-Seizing wire rope.

3. The seizing should be spaced a distance equal to

twice the diameter of the wire rope.

Example: 2 x 3/4-inch-diameter rope = 1 1/2 inches.

Space the seizing 2 inches apart.

A common method used to make a temporary wire

rope seizing is as follows:

Wind on the seizing wire uniformly, using tension

on the wire. After taking the required number of turns,

as shown in step 1, twist the ends of the wires

counterclockwise by hand, so the twisted portion of the

wires is near the middle of the seizing, as shown in

step 2. Grasp the ends with end-cutting nippers and twist

up slack, as shown in step 3. Do not try to tighten the

seizing by twisting. Draw up on the seizing, as shown

in step 4. Again twist up the slack, using nippers, as

shown in step 5. Repeat steps 4 and 5 if necessary. Cut

ends and pound them down on the rope, as shown in

step 6. If the seizing is to be permanent or if the rope is

1 5/8 inches or more in diameter, use a serving bar, or

iron, to increase tension on the seizing wire when

putting on the turns.

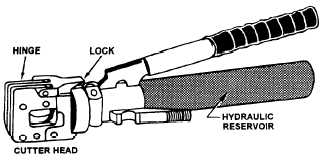

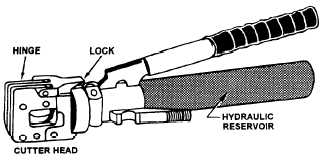

Wire rope can be cut successfully by a number of

methods. One effective and simple method is to use a

hydraulic type of wire rope cutter, as shown in

figure 13-19. Remember that all wire should be seized

before it is cut. For best results in using this method,

place the rope in the cutter so the blade comes between

the two central seizings. With the release valve closed,

jack the blade against the rope at the location of the cut

and continue to operate the cutter until the wire rope is

cut.

MAINTENANCE OF WIRE ROPE

Wire rope bending around hoist drums and sheaves

will wear like any other metal article, so lubrication is

just as important to an operating wire rope as it is to any

other piece of working machinery. For a wire rope to

Figure 13-19.—Hydraulic type of wire rope cutter.

13-9