Figure 13-16.-Transferring wire rope from reel to drum.

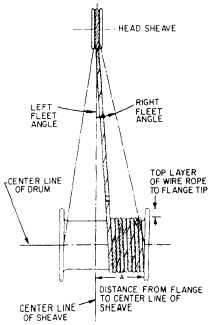

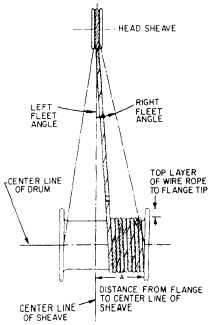

Figure 13-17.—Fleet angle relationship.

TOP or from BOTTOM TO BOTTOM, as shown in

figure 13-16.

Fleet Angle

The fleet angle is formed by running wire rope

between a sheave and a hoist drum whose axles are

parallel to each other, as shown in figure 13-17. Too

large a fleet angle can cause the wire rope to climb the

flange of the sheave and can also cause the wire rope to

climb over itself on the hoist drum.

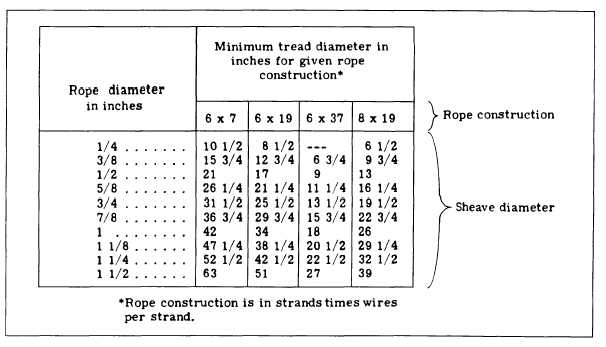

Sizes of Sheaves

The diameter of a sheave should never be less than

20 times the diameter of the wire rope. An exception is

6 x 37 wire for which a smaller sheave can be used,

because this wire rope is more flexible.

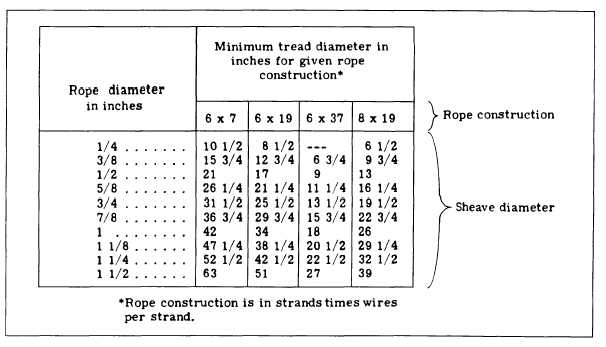

The chart shown in table 13-1 can be used to

determine the minimum sheave diameter for wire rope

of various diameters and construction.

Reverse Bends

Whenever possible, drums, sheaves, and blocks

used with wire rope should be placed to avoid reverse

or S-shaped bends. Reverse bends cause the individual

wires or strands to shift too much and increase wear and

fatigue. For a reverse bend, the drums and blocks

affecting the reversal should be of a larger diameter than

Table 13-1.–Suggested Minimum Tread Diameter of Sheaves and Drums

13-8