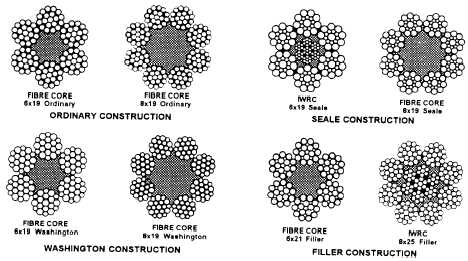

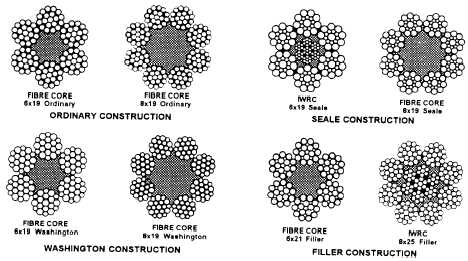

Figure 13-2.—Common strand construction.

constructions are Ordinary, Seale, Warrington, and

Filler (fig. 13-2).

. Ordinary construction wires are all the same

size.

. Seale is where larger diameter wires are used on

the outside of the strand to resist abrasion and smaller

wires are inside to provide flexibility.

l Warrington is where alternate wires are large

and small to combine great flexibility with resistance to

abrasion.

l Filler is where very small wires fill in the valleys

between the outer and inner rows of wires to provide

good abrasion and fatigue resistance.

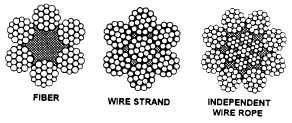

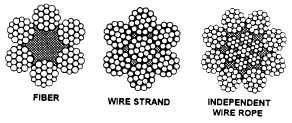

Core

The wire rope core supports the strands laid around

it. The three types of wire rope cores arc fiber, wire

strand, and independent wire rope (fig. 13-3).

Figure 13-3.—Core construction.

. A fiber core may be a hard fiber, such as manila,

hemp, plastic, paper, or sisal. The fiber core offers the

advantage of increased flexibility. It also serves as a

cushion to reduce the effects of sudden strain and acts

as an oil reservoir to lubricate the wire and strands (to

reduce friction). Wire rope with a fiber core is used when

flexibility of (he rope is important.

. A wire strand core resists more heat than a fiber

core and also adds about 15 percent to the strength of

the rope; however, the wire strand core makes the wire

rope less flexible than a fiber core.

. An independent wire rope core is a separate

wire rope over which the main strands of the rope are

laid. This core strengthens the rope, provides support

against crushing, and supplies maximum resistance to

heat.

GRADES OF WIRE ROPE

The three primary grades of wire rope are mild plow

steel, plow steel, and improved plow steel.

Mild Plow Steel Wire Rope

Mild plow steel wire rope is tough and pliable. It

can stand repeated strain and stress and has a tensile

strength (resistance to lengthwise stress) of from

200,000 to 220,000 pounds per square inch (psi). These

characteristics make it desirable for cable tool drilling

and other purposes where abrasion is encountered.

13-2