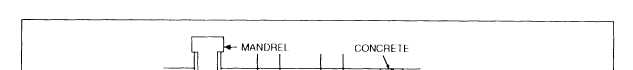

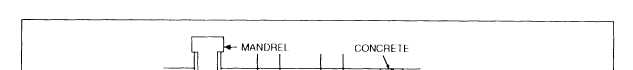

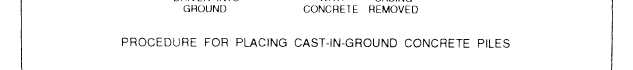

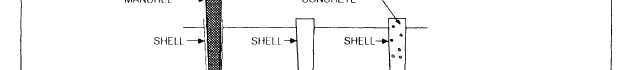

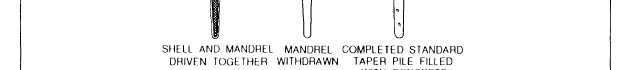

. Cast-in-place concrete piles may be used

when conditions are favorable. They are made by

pouring concrete into a tapered hole or cylindrical

form previously driven into the ground or into a hole

in the ground from which a driven mandrel has been

withdrawn.

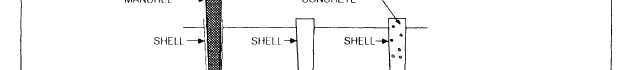

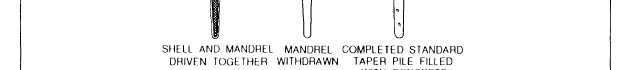

The left-in-place form may be a steel

shell heavy enough to be driven without a mandrel, or

it may be a steel form designed for driving with a

mandrel that is removed on completion of driving (fig.

12-77).

20. Composite piles. Composite piles are formed of

one material in the lower section and another material

in the upper section (fig. 12-78). A composite pile that

is constructed of wood and concrete is used to support

loads of 20 to 30 tons.

A composite pile that is

constructed of steel and concrete is used to support loads

up to 50 tons. As shown in figure 12-78, the first section

of wood or steel is driven first, then a mandrel and steel

casing are driven on top of the first section. The mandrel

is removed and the casing is filled with concrete.

21. Sheet piles.

Sheet piles are special shapes of

interlocking piles that are made of steel, wood, or formed

concrete which are used to forma continuous wall to resist

horizontal pressures, resulting from earth or water loads.

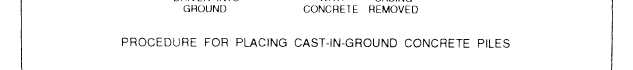

Figure 12-77.—Cast-in-place concrete piles.

12-54