the primary clamping screw firmly by hand. When the

clamping device is secured in place, turn the handle on

the bottom of the reaction screw. This handle swivels up

and down to permit maximum movement of the

clamping device side arms to ease hooking the ram

cylinder into place.

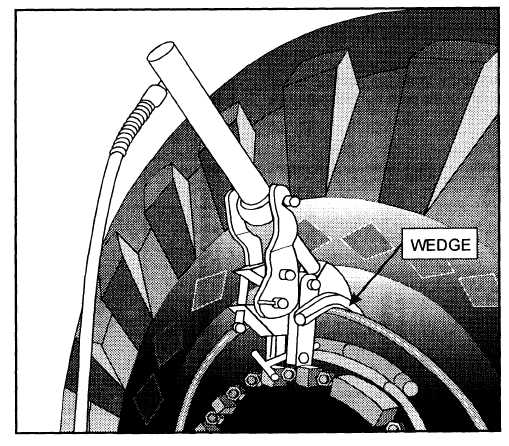

The hydraulic cylinder and shoe assembly (fig.

3-35) are actuated by a pump. The pump applies

hydraulic pressure that forces the ram with the attached

shoe down between the rim flange and tire bead. This

action separates the tire bead and rim.

When securing the ram to the clamping device,

place the ram and shoe assembly between the arms of

the clamping device where the bracket of the cylinder is

secured into the notches of the clamping device side

arms, as shown in figure 3-35.

Applying pressure to the hydraulic cylinder forces

the shoe down over the clamping device, as shown in

figure 3-35. The jaws of the clamping device acts as a

guide for the shoe. The convex side of the shoe bears

against the sidewall of the tire, forcing it inward between

the tire bead and rim flange, thus breaking loose the bead

from the rim.

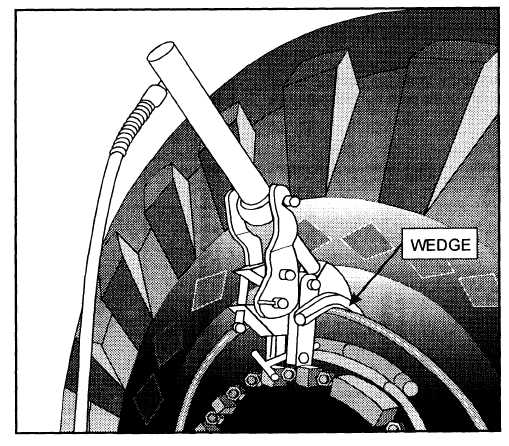

Figure 3-36 shows how the wedges are placed on

each side of the shoe assembly to hold the bead of the

tire away from the rim flange so that the shoe assembly

can be easily removed. After the shoe has been forced

between the tire bead and rim flange and freed from that

portion of the tire bead, the wedges are inserted to keep

the tire bead separated from the rim. Pressure is then

removed from the hydraulic cylinder slowly. The

hydraulic cylinder and clamping device are then

removed from the rim and the clamping device is placed

approximately 90 degrees from the wedge. This process

is continued until the tire bead is completely free from

the rim flange.

Cold Patches

Cold patches are used to repair punctures and small

breaks or holes in tubes. The procedure for applying a

cold patch is accomplished by the following steps:

Figure 3-36.—Operation of hydraulic cylinder and shoe.

3-19