The operation of a dual system master cylinder is

basically the same as a single master cylinder. However,

the dual system master cylinder has two separate

hydraulic pressure systems. One of the hydraulic

systems normally is connected to the front brakes and

the other system to the rear brakes. If either the front or

rear hydraulic system fails, the other system remains

operational.

The master cylinder, like other parts in the brake

system, is subject to wear, leaks, and deposits or

corrosion on the cylinder wall and piston. Part of your

prestart operation is to check the cylinder reservoir fluid

level and add clean brake fluid to maintain the

manufacturer’s specifications.

The brake lines transmit fluid and pressure from the

master cylinder to the wheel cylinders, which are

mounted on the brake-backing plate, and change the

hydraulic pressure into mechanical force. Inside each

cylinder are two pistons that move in opposite directions

by hydraulic pressure which pushes the brake shoes

against the brake drum or disc. The brake shoes are made

of steel that transmits force to the lining which is

attached to the face of the shoe and makes contact with

the brake drums or discs. During contact with one

another, the lining and the drum or disc create the

frictional surface that gives the braking effect.

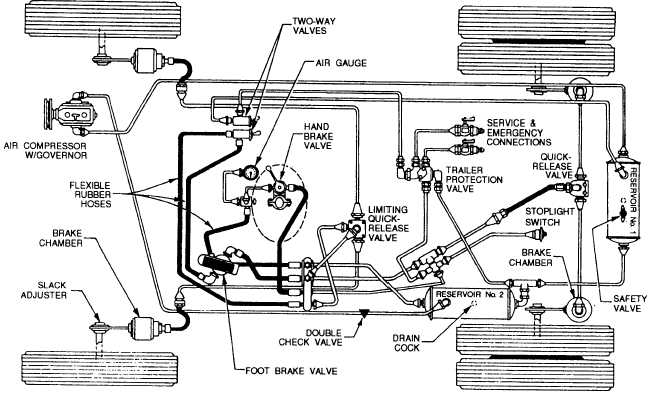

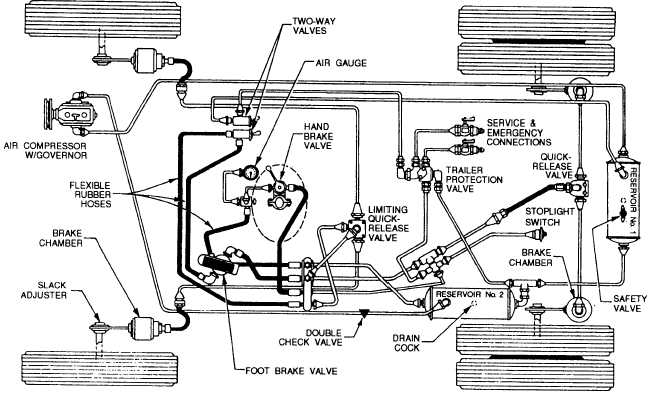

AIR BRAKE SYSTEM

An air brake system uses compressed air to apply

the brakes. Air under pressure can be conveniently

stored and carried through lines or tubes. Considerable

force is available for braking since operating air

pressure may be as high as 100 psi. All brakes on a

vehicle and on a trailer (when one is used) are operated

together by a brake valve. This valve and the relative

location of most of the basic assemblies of an air brake

system are shown in figure 3-44.

Air Compressor

The air compressor pumps air into the air storage

tanks (reservoirs). The air compressor is driven by the

engine through gears or a V-belt. The compressor may

be air-cooled or may be cooled by the engine lubrication

system. It may have its own oil supply or be lubricated

by engine oil. If the compressor has its own oil supply,

the oil should be checked during your prestart

operations.

Governor

The governor controls the air compressor output.

When air tank pressures rise to the cutout level at about

Figure 3-44.—Typical air brake system.

3-24